Mahle digitizes the workshop

The Aftermarket division of Mahle GmbH moved from Stuttgart to Schorndorf. On the occasion of the opening of the European headquarters, innovative DIGITAL SOLUTIONS for the automotive workshop were presented.

Mahle digitizes the workshop

The spacious U-shaped building complex in Schorndorf near Stuttgart houses the automotive supplier's spare parts warehouse as well as offices, conference and training rooms. The employees at the desks enjoy spacious rooms flooded with daylight, the forklift drivers in the warehouse are supported by modern shelving robots. In the packages that they load into the cargo holds of the waiting trucks, spare parts and workshop equipment from the brands Mahle Original, Brain Bee, Behr, Clevite, Izumi, Knechtfilter and Metal Leve have previously been put together according to customer requirements. Olaf Henning, Managing Director of Mahle Aftermarket, is quite satisfied with the demand for piston rings, filters, turbochargers and other spare parts for the conventional drive train: “The combustion engine is far from finished, on the contrary - it is constantly being improved.” Mahle also has a strong presence on the market in the workshop equipment sector with state-of-the-art diagnostics and air conditioning service devices. “We want to be the iPhone for the workshop, so to speak, and have therefore placed great emphasis on the usability of our devices during development,” explained Henning. Mahle first has the prototypes of its new devices extensively tested in partner workshops before they are optimized, mass-produced and brought onto the market. Regular updates via the Internet keep the air conditioning service and diagnostic devices permanently up to date with the latest technology and thereby extend the time until the inevitable retirement. Good news for the Schorndorf-based workshop supplier: traditional setting devices also remain in demand. Olaf Henning: “The classic car boom is giving us increasing demand for oscilloscopes, which are needed to set the optimal ignition point of a carburetor engine.”

“We want to be the iPhone for the workshop, so to speak.”OLAF HENNING, CEO MAHLE AFTERMARKET

CALIBRATION REVOLUTION

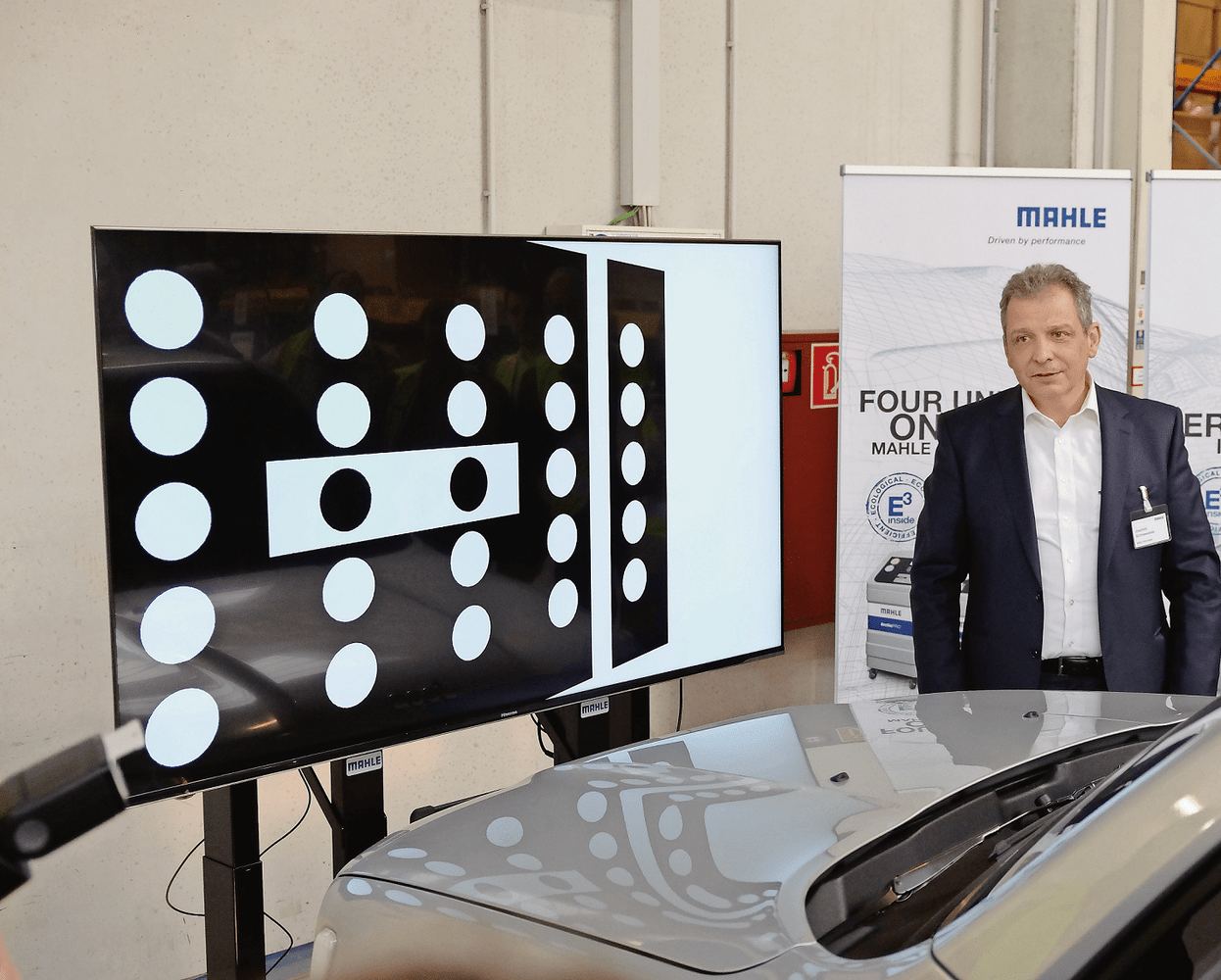

Joachim Schneeweiss, Sales Manager of Mahle Service Solutions, presented the assembled media representatives with a truly revolutionary device for calibrating driver assistance systems during the opening of the Mahle European headquarters.

“When we had the idea, we could hardly believe that no one else had thought of it before,” says Schneeweiss. In fact, setting up the cameras, radar screens and ultrasonic sensors that support traffic sign recognition, the emergency braking assistant and the adaptive cruise control is currently a tedious and time-consuming affair in everyday workshop life. Each vehicle model requires its own calibration board, which must be clamped into a frame and positioned at a centimeter-precise distance from the vehicle. The challenge: Even minimal deviations from the geometric travel axis can lead to failures of the assistance systems during driving. Workshops have previously had to accept high investment and operating costs for the purchase and storage of a large number of calibration boards. The alternative from Mahle: Instead of several analog calibration boards, the “TechPro Adas” system uses a digital flat screen onto which the measuring points that match the individual vehicles are uploaded from a database simply with a mouse click. “With our digital calibration board, we reduce the calibration time and space requirements to a minimum and thus significantly reduce both the purchase and ongoing operation costs,” explained Schneeweiss. Compared to a conventional analog calibration solution, the TechPro Adas system saves the workshop time by up to 80 percent. The patent-pending system is also constantly updated online, and the vehicle coverage is also constantly being expanded. “In the next few years, both the number of driver assistance systems and the proportion of cars and trucks equipped with them are expected to increase significantly - this will significantly change the work of workshops,” Olaf Henning is convinced. To make it easier for the workshop to get started with the innovative TechPro Adas system, Mahle also offers a leasing model as an alternative to purchasing.

DATA & FACTS

Mahle Aftermarket employs around 1,600 people at 25 locations worldwide and provides around 150,000 spare parts. Over 140 engine and vehicle manufacturers use Mahle engine parts and filters.

Suche

Suche

Mein Konto

Mein Konto