The turbocharger and the engine oil

The technical experts at TurboTec, specialists in the regeneration of turbochargers, show in this technical article how damage to bearings and rotating parts can be avoided.

The turbocharger and the engine oil

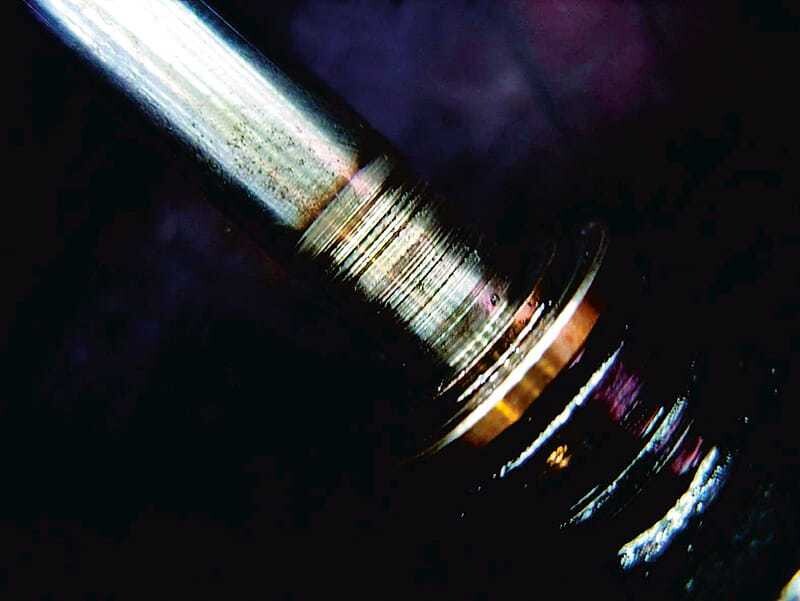

The majority of turbochargers have a so-called floating bearing. In the middle part of the housing are the oil supply lines through which the core and the bearings of the shaft are lubricated. The rotating part consists of compression blade wheel, turbine wheel and rotor shaft. This has one or two bearing sleeves that are responsible for absorbing the torque and rotational forces generated by the exhaust gas. Axial bearings are also installed to compensate for the shaft forces. If the rotating surfaces are not completely covered with lubricant, damage due to dry friction or mixed friction can occur.

Optimal wet friction

In order to maintain the desired optimal wet friction, clean engine oil must reach the bearings in sufficient quantities and at sufficient pressure. In addition, the engine oil must not be contaminated and must meet the manufacturer's quality criteria. Even the smallest interruptions in the oil supply can lead to turbocharger failure. The consequences are increased temperature and the well-known “wave game”. The most common causes of inadequate lubrication are contamination of the oil supply line or the sieves, damage to the oil pan, too low an oil level or blockage of oil lines. The lubricating properties of the oil are also severely impaired when mixed with fuel or cooling water. Poorly functioning injectors or frequent regeneration of the particle filter can cause fuel to mix with the lubricating oil on the cylinder walls. But dirt particles that get into the oil after a replacement or repair can also scratch the shaft or bearing. A cylinder head that has been mechanically treated must therefore be cleaned thoroughly. Further information: www.turbo-tec.eu/at/

Suche

Suche

Mein Konto

Mein Konto