Battery repair is becoming a business

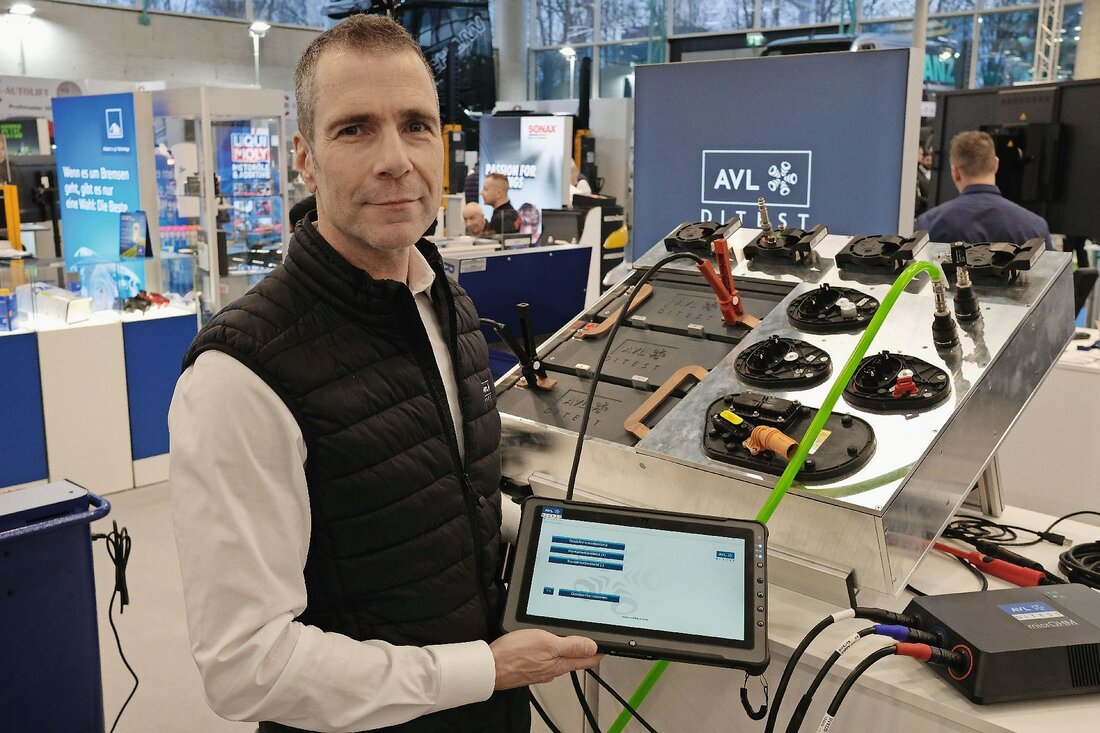

In an interview, Otto Loacker, Area Sales Manager at the Graz measurement technology specialist AVL DiTest, talks about the future of the workshop business in the light of electromobility.

Battery repair is becoming a business

VEHICLE ECONOMY:AVL DiTest offers a wide portfolio of testing devices for electric cars - are the tools actually in demand by workshops?

OTTO LOACKER: In fact, demand for our diagnostic tools for electric vehicles is increasing rapidly. More and more workshops are realizing that there is an interesting upcoming business model in the maintenance and repair of vehicle batteries. In the past, the main demand was for devices for disconnecting the voltage, which were needed for general service work on the electric vehicle, such as changing tires. Today, there is also increasing interest among independent workshops in how you can repair batteries, what tools you need and how you can get the necessary manufacturer data.

Which diagnostic tools does AVL DiTest have in its range for working on high-voltage systems?

Our “HV Safety 2000” is suitable for checking the absence of voltage, measuring the insulation resistance and measuring the potential equalization. We offer our “Worksafe” tool for measuring the insulation resistance and the “Microhm” device for checking the battery condition. We also have the “noLEAK” test device in our range, which can be used to measure the tightness of the battery housing and the cooling circuit after a repair has been carried out. This is done by applying pressure and monitoring the pressure drop.

How do you assess the future of electromobility? Will this prevail over the combustion engine?

The development of vehicles is progressing rapidly - performance is getting better, batteries are getting smaller and charging cycles are getting shorter. Only the future will show whether and how the workshops will be able to earn money from servicing and repairing these vehicles. Electric cars have significantly fewer wear-intensive components on board than combustion cars. But the question is how susceptible the electrical systems will be to repairs after the warranty period expires - that remains to be seen.

At AutoZum you will also be showing the ADS 310 air conditioning service device for CO2 air conditioning systems. How common is the CO2 refrigerant R744 compared to the conventional refrigerant R1234yf?

The CO2 air conditioning system is superior to today's R1234yf system in terms of efficiency, cooling dynamics and environmental compatibility. The new Ford models Capri and Explorer already have CO2 air conditioning systems on board, as do the VW electric models ID3, ID4 and ID5 and various premium models from Mercedes. With the AVL DiTest ADS 310 air conditioning service device, the workshop has the opportunity to carry out repairs and maintenance on CO2 air conditioning systems for the first time. The advantage for the environment is that CO2 as a refrigerant is not harmful to health or the climate and can therefore be easily released into the outside air. In addition, CO2 is significantly more economical at around a tenth of the price compared to conventional refrigerants.

Suche

Suche

Mein Konto

Mein Konto