Turbotwins: The original remains unmatched

The Turbo Twins, Austria's largest specialist for TURBOCHARGERS of all makes, know from experience that repairing a turbocharger cannot compete with an original spare part in terms of reliability.

Turbotwins: The original remains unmatched

Walter Müllberger, who runs the traditional company Turbo Twins in Vienna-Simmering together with his twin brother Manfred, has been gaining experience in both the replacement and repair of brand-name turbochargers for 25 years. “For several years now, we have been concentrating on trading original spare parts in the passenger car sector, as the reliability of so-called regenerated turbochargers simply cannot keep up with them,” says Müllberger and continues: “Cheap offers of replacement turbochargers, which seem temptingly cheap at first glance, often turn out to be expensive bad purchases afterwards.”

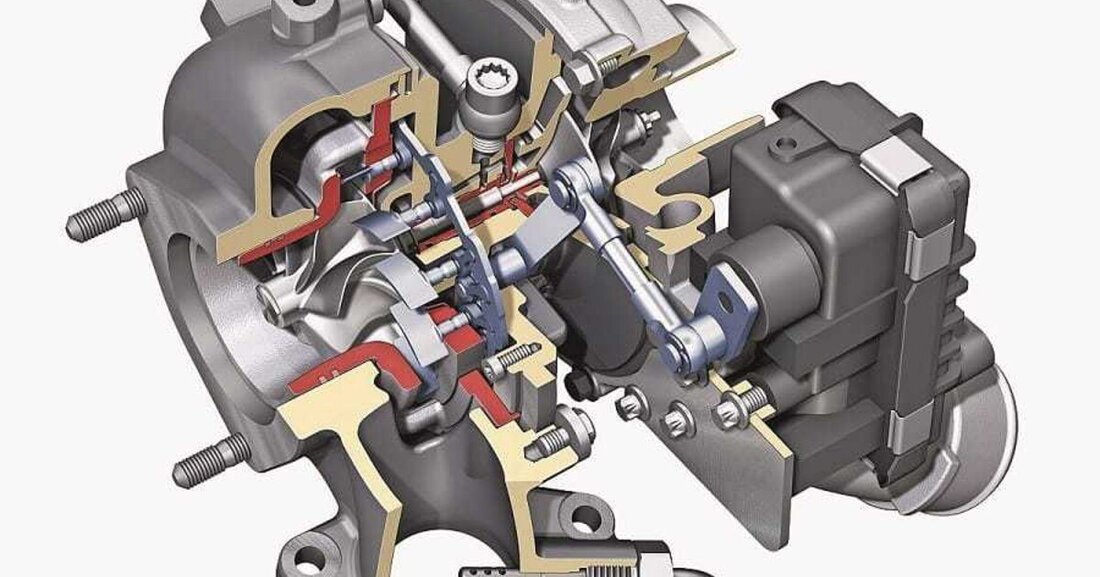

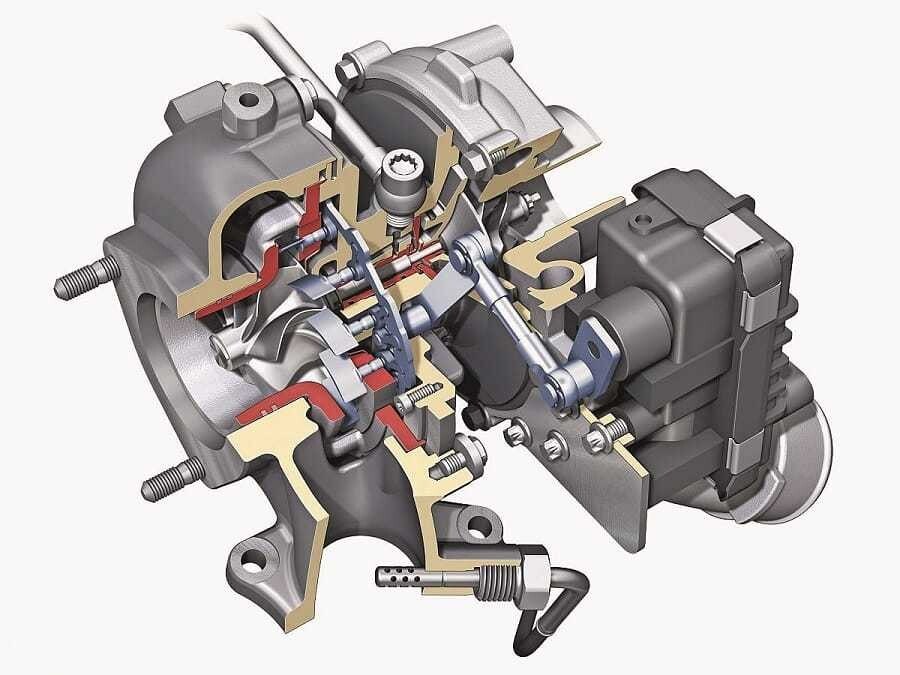

SENSITIVE BALANCE

Turbochargers are developed and manufactured precisely to suit the respective engine and in accordance with the specifications of the engine and vehicle manufacturers. The complex units have been tuned for maximum performance at the factory and have been continually optimized over the course of development. The interaction of the individual components of a modern turbocharger works so perfectly that once individual components have been replaced, the delicate balance can no longer be restored to 100 percent. The result: Manufacturers no longer offer spare parts for most modern turbochargers, but instead recommend replacing the entire unit in the event of damage. “Our experience shows that only the original spare parts actually have the required material quality and manufacturing tolerances for smooth operation,” say the Turbo Twins. But since original spare parts are naturally more expensive compared to regenerated units, low-cost suppliers are now entering the supposed gap in the market, offering used and replica parts mainly from Far Eastern production. “These parts in no way meet the requirements for a proper repair,” warns Walter Müllberger. For example, the reuse of highly stressed parts such as turbine shafts or compressor wheels is not permitted for reasons of material fatigue.

EXPENSIVE CONSEQUENCES

Since the replicas are not structurally identical to the original turbochargers and the tolerances cannot be maintained during production, the result is usually an increase in a vehicle's consumption and emissions. Improperly manufactured or repaired turbochargers result in a reduction in engine performance and, in the worst case, there is even a risk of engine damage. “The use of so-called replacement turbochargers represents a high risk for workshops, even if the customer excludes the workshop’s liability in writing,” warn the Turbo Twins. In the event of possible claims for damages, a decision is almost always made against the company in court, as the specialist workshop must be able to determine the difference in quality before installation. Conclusion Walter Müllberger: "There is no alternative to a new original equipment manufacturer turbocharger. We only carry out repairs if a turbocharger manufacturer also offers original spare parts." But today this only occurs in tractors, ships, stationary engines or older car turbochargers.

Suche

Suche

Mein Konto

Mein Konto