New bearings for electric cars from Schaeffler

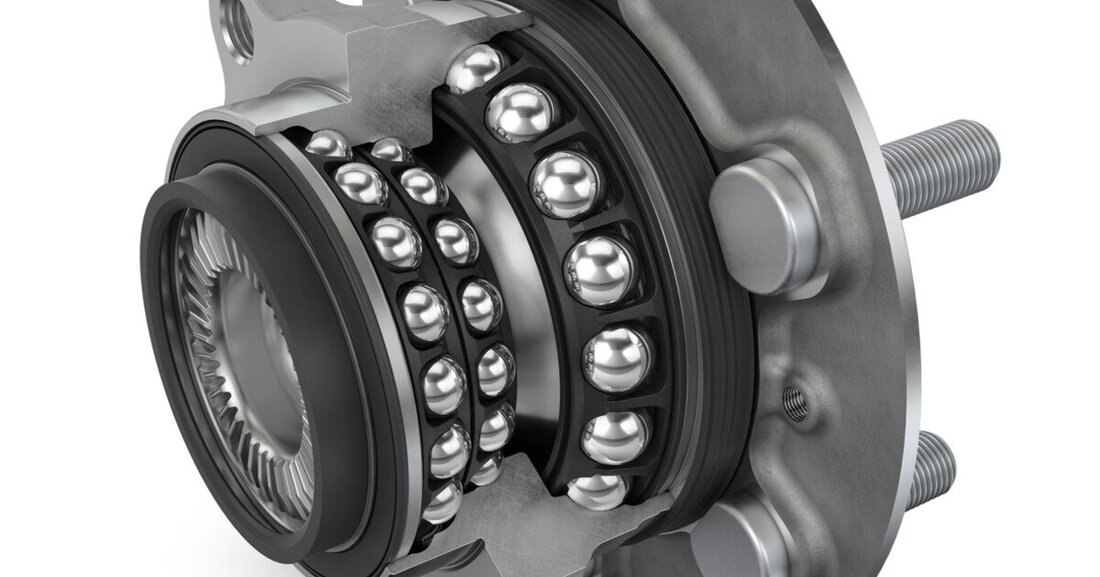

Schaeffler's TriFinity three-row bearing offers greater rigidity and service life compared to a standard bearing with two rows of balls.

New bearings for electric cars from Schaeffler

Innovative storage solutions play a central role in sustainable mobility as they make drive trains and chassis systems more efficient. With electrified vehicles, every energy saving means more range. Each bearing point becomes the focus of vehicle development and offers greater customer benefit through friction optimization. Schaeffler has recognized the potential of innovative bearings and is presenting further product innovations specifically for electric vehicles with the three-row wheel bearing TriFinity and the high-performance ball bearing with centrifugal disk

“Innovative bearing technologies are an integral part of our product DNA and are of central importance for the successful business development in the Automotive Technologies division,” says Matthias Zink, Board Member for Automotive Technologies at Schaeffler AG. “With efficient and high-precision products, Schaeffler will equip not only conventional drives but also electrified drive trains and chassis systems with its bearing solutions and make them even better and more sustainable.”

With TriFinity, Schaeffler offers a three-row wheel bearing that is intended for use in electrified drive trains. Compared to a standard bearing with two rows of balls, the TriFinity allows more axle shaft to be transferred with a significantly longer service life and stiffness without changing the bearing dimensions. Furthermore, preloaded tapered roller bearing units can be replaced with this innovative ball bearing design. Changing from the tapered roller to a ball results in a significant improvement in friction torque and stiffness, resulting in a 0.7 percent reduction in power consumption per vehicle in the FTP75 cycle.

The combination with the Schaeffler spur gearing and the TriFinity realizes downsizing solutions and thus wheel bearing units with smaller diameters, which results in less bearing and seal friction, optimized bearing weight and improved CO2-Footprint leads. The backlash-free spur gearing enables transmission of up to 50 percent more drive torque with less weight, easier assembly and reduced noise for electric vehicles with the same bearing dimensions.

Suche

Suche

Mein Konto

Mein Konto