E-axle repair business?

We asked experts from the supplier industry whether the drive solutions for electric cars can even be repaired.

E-axle repair business?

The increasing spread of electromobility is causing the workshop industry to fear for its future. The fact is: You won't be able to sell so many tires, brakes and special lubricants to customers with electric cars in order to compensate for the delta to the repair business with combustion engines. Spark plugs, air filters, engine oil and some other wear parts of the combustion engine will only be needed in classic car workshops. This is desirable from a sustainability perspective and from a customer perspective, because fewer wearing parts means less spare parts production and fewer follow-up costs for end customers. The future of vehicle drive, which is already established today, is called the e-axle. Depending on the model, this bundles previously completely separate assemblies such as drive motor, gearbox, control units and thermal management into just one closed system. Most car manufacturers have already come to terms with this. They practically buy the majority of the drive unit from the supplier as a complete package and build vehicles around it that correspond to their brand philosophy. This practice massively simplifies automobile construction, reduces costs and – in a perfect world – could significantly reduce the costs of individual mobility. Especially since e-axles are said to be significantly less wear-and-tear than combustion engines due to their design.

Each manufacturer cooks its own soup and develops e-axles for large-scale production in close cooperation with the respective car manufacturer. The Graz drive train developer AVL, for example, offers to tailor the entire drive system according to the customer's specifications. Drivetrain construction, once a core competency of automobile manufacturers, is increasingly moving into the hands of suppliers. One consequence of this: the number of different drives will be reduced. This can also be a blessing for the workshops: While independent workshops today have to be able to repair many different brands from A to Z, things could become much easier with e-axles and standard drives that are practically off the shelf. Anyone who is familiar with the systems of the major suppliers will probably be able to get almost any car running again in the future. Conclusion: The manufacturers' idea of efficiency, to go far with fewer components, could also open up a wider range of customers to workshops and make it easier to carry out repairs across brands.

We know it from smartphones: They are built in such a way that repairs and even a simple battery replacement cannot be carried out by the customer themselves. To ensure that such a practice does not spread to modern vehicles, interest groups at EU level are ensuring that batteries, for example, must be built to be repairable in order to enable independent workshops to repair them. In addition to the batteries, the e-axles will be the most important component in the e-car. It is quite possible that there will soon be legal improvements here. To ensure that the maintenance costs for electric cars for end consumers do not skyrocket, there needs to be fair competition between branded and independent workshops. However, from today's perspective it is not yet clear how repairable e-axles will actually be. "Schaeffler develops e-axles in various variants in close coordination and individually for each automobile manufacturer. The degree of repairability therefore varies depending on customer requirements," says Alex Moor, project manager for e-drive at Schaeffler Automotive Aftermarket. And Gerhard Meister, Vice President Electrification at AVL, explains from his perspective: "With electric drive units, it is conceivable that the systems can be repaired by replacing mechanical components such as bearings, seals, gears or even actuators by specially trained specialists. Things become critical with safety-relevant high-voltage components, such as the electric motor and the power electronics." There, due to special processes and testing devices, safety-relevant work must be carried out "according to the "replacement unit" model. But: The manufacturer or specialized repair companies could reprocess the replaced unit and put it to further use. A similar tenor, only less precise, also exists at Bosch. In response to our query, it says: "Bosch is careful to increase the sustainability of its products throughout the entire life cycle. When developing our products, we therefore generally also take the aspect of the Repairability. Determining repair specifications is largely the responsibility of the respective automobile manufacturer that brings the vehicles onto the market.”

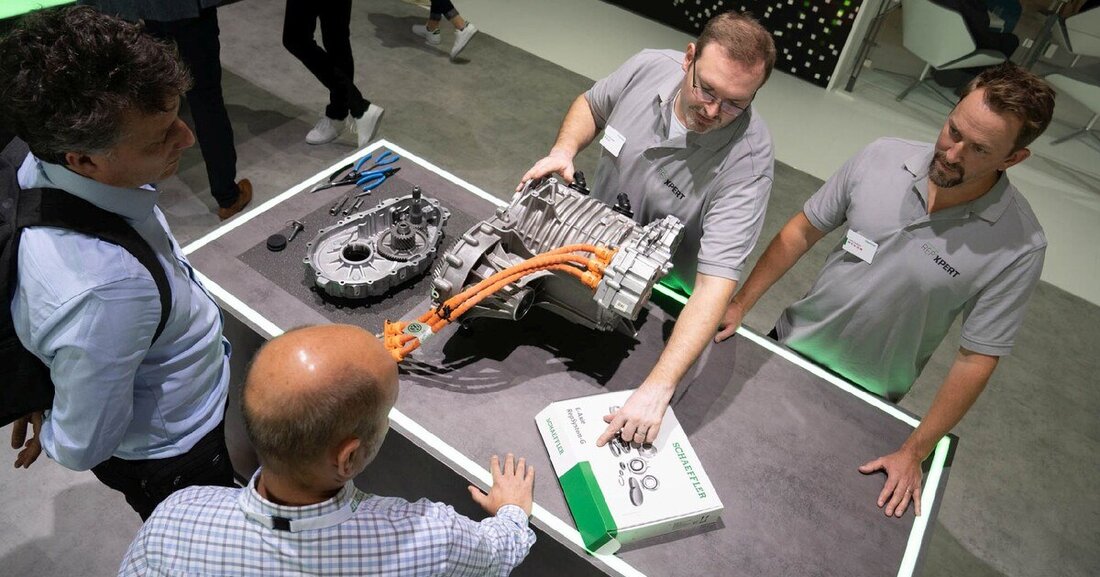

So if the manufacturer himself specifies how repairable his e-axles should be in the future, he can very well determine for himself how much business the independent workshops will receive the day after tomorrow. From a commercial perspective, it might be more attractive for manufacturers if the repair options are limited so that they have to pay larger chunks in the event of damage. On the other hand, when it comes to sustainability, no one wants to be in the shadow of their competitors, and inexpensive repairs to individual components are more resource-efficient than completely replacing an e-axle. Manufacturers must therefore make a fundamental market economy decision during the planning stage: How liberal should I set up the repair business for my products? The first trends towards liberalizing the market were started by one supplier: Schaeffler. Schaeffler itself offers the 2-1, 3-1 and 4-1 E-axle, where either the motor, transmission and power electronics or, in addition, the thermal management are combined into one component, the E-axle.

Since there were early reports from the market that the VW e-Golf's transmission, which only has one gear, was occasionally causing problems, Schaeffler is offering the first repair kit for e-axles: the "E-Axle RepSystem G". "Thanks to our special know-how, our repair solution for e-axles contains all the relevant components for professional transmission repairs. This not only makes repairs easier for workshops, but also makes ordering the parts particularly convenient and safe," says Alex Moor. In principle, high-voltage training is a prerequisite for work on electric drive trains, and according to Moor, Schaeffler will continue to have appropriate repair instructions and product training available for independent workshops, including in the area of e-mobility. Conclusion: Certain repairs are already possible on e-axles, but require appropriate know-how, especially completed high-voltage training. From the current perspective, however, it appears that individual components of the e-axles will be replaced completely in the future in order to quickly get the car fit again. And only afterwards are the removed individual components reprocessed or repaired in repair shops (or directly at the manufacturer), provided their continued use makes sense and is economically feasible. The enterprising mechanic now probably recognizes a similar opportunity as he did back then with the specialized repair of automatic transmissions or speedometer units. In any case, the fact that e-axles can be easily unscrewed and repaired in the workshop does not seem to be part of the manufacturer and supplier industry's plan.

Suche

Suche

Mein Konto

Mein Konto