Liqui Moly and the art of mixing

In the company's own laboratory in Ulm, Liqui Moly shows us the effects and possible uses of ADDITIVES and two new service devices that can increase sales in workshops.

Liqui Moly and the art of mixing

Additives are a hot topic right now. They are found in premium fuels and high-quality motor oils. For lubricants, the proportion is between 16 and almost 25 percent. The Ulm-based company Liqui Moly focused on the marketing of additives decades ago. The Liqui Moly employees prefer to use the word “chemical tools” for additives. It illustrates how the lubricant company uses its products: as a problem solver. At a press workshop in Ulm, head of research and development David Kaiser explained the world of additives to us in more detail.

THREE TARGET GROUPS

Basically, Liqui Moly pursues both a B2B and B2C sales strategy. “Pro Line” is the name of the recipes that are primarily intended for specialist workshops. The additive products are more concentrated and their application/dosing must therefore be more precise. The idea behind it: With the Pro Line offering, such as fuel system cleaners, engine and transmission flushes, workshops should generate more sales as well as save their end customers expensive repairs and score points with specialist knowledge. The end consumer products that you can get from well-known accessories retailers are easier to use, but their efficiency is also lower. The third target group are fleet operators and transport companies, as certain additives can increase engine durability and reduce fuel consumption. In truck and bus fleets, where fuel costs are an enormous cost factor, even the slightest savings in fuel consumption can add up to several thousand euros per year.

THE EFFECT

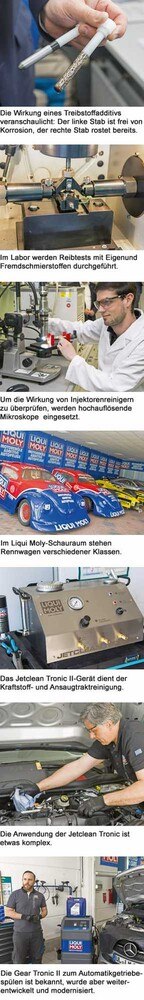

To illustrate the effect of additives, David Kaiser shows a simple experiment: two steel rods are dipped into pure, unadditized gasoline and heated. The gasoline system care is added to a container to protect components of the fuel system from corrosion. After a good hour you can see that the fuel without additives has left clear traces of rust, while the other rod looks like new. Another experiment concerns the solid lubricant in the oil additive Cera Tec. The ceramic engine protection is intended to create a smooth running effect inside the engine and thus reduce fuel consumption and increase service life. The ceramic powder adheres almost magnetically to metal surfaces. A spoon is dipped into a glass with liquid and Cera Tec and sure enough, only the metal spoon is surrounded by the orange slip improver. If you take a thin layer of the powder between your fingers, you will immediately feel the significant reduction in friction. The injector cleaning additive ensures that carbon deposits around the injectors are removed over time and that the injection mist can again be distributed undisturbed in the combustion chamber. In engine oils, the additive components are so small that they are not recognized and bound as dirt particles. Fuel additives are primarily used to clean the injection system for older vehicles and can be used prophylactically to prevent expensive injector repairs. Cooler additives can even seal small leaks.

PRODUCT SYSTEM

Liqui Moly is also showing the Gear Tronic II, an improved version of its automatic transmission oil service station for changing and flushing in one operation. Gear Tronic II was created in cooperation with Mahle and is manufactured exclusively for Liqui Moly. The advantage: All of the used oil, including impurities and downforce, is disposed of and the gearboxes then run cleaner. The Jetclean Tronic II, a device for cleaning the fuel system and the intake tract, is completely new. The device is suitable for petrol and diesel models; you just have to change the fuel filter and the cleaning additive for the respective drive type.

Suche

Suche

Mein Konto

Mein Konto