Falken makes tire wear measurable

Thanks to new technology, Falken may be making an important leap in future tire development.

Falken makes tire wear measurable

In a joint project, an innovative power generator was developed that uses the rotation of a tire to generate electricity and supplies energy to the peripheral sensors installed in the tire without relying on batteries: This “Miniature Energy Harvester” is the result of the cooperation between the parent company of Falken, Sumitomo Rubber Industries, and Kansai University in Japan.

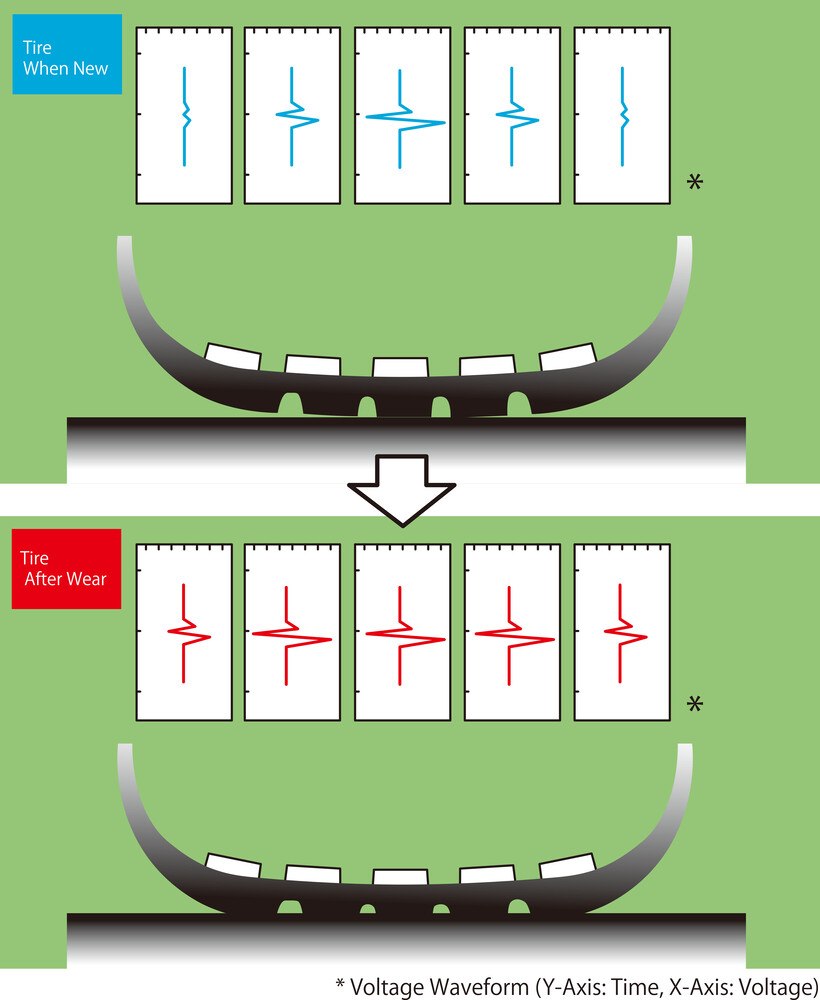

With the use of this energy harvester, it has been possible to demonstrate sustainable techniques for measuring tire wear. It allows the calculation of the tire contact area and wheel revolutions, as well as the voltage level of the harvester based on amplitude changes induced by rotation of the tires.

The data can then be extrapolated to determine tire wear. At the same time, the research team has developed a technique for measuring the tire contact patch by installing several miniaturized energy harvesters in each tire. These mini power generators are used to generate contact patch data across the tire width. These new technologies provide important information that can be incorporated into future tire developments.

“The Energy Harvester is a big step towards implementing our sustainability policy; the technology supports us in developing tires with an optimized contact area and therefore a longer service life,” says Bernd Löwenhaupt, Managing Director at Sumitomo Rubber Europe GmbH, commenting on the innovation.

Suche

Suche

Mein Konto

Mein Konto