Electric cars - lubricated and cooled

As electromobility becomes more widespread, will lubricant manufacturers soon be able to close their doors forever? Not at all, because the electric drive train also needs to be lubricated and cooled.

Electric cars - lubricated and cooled

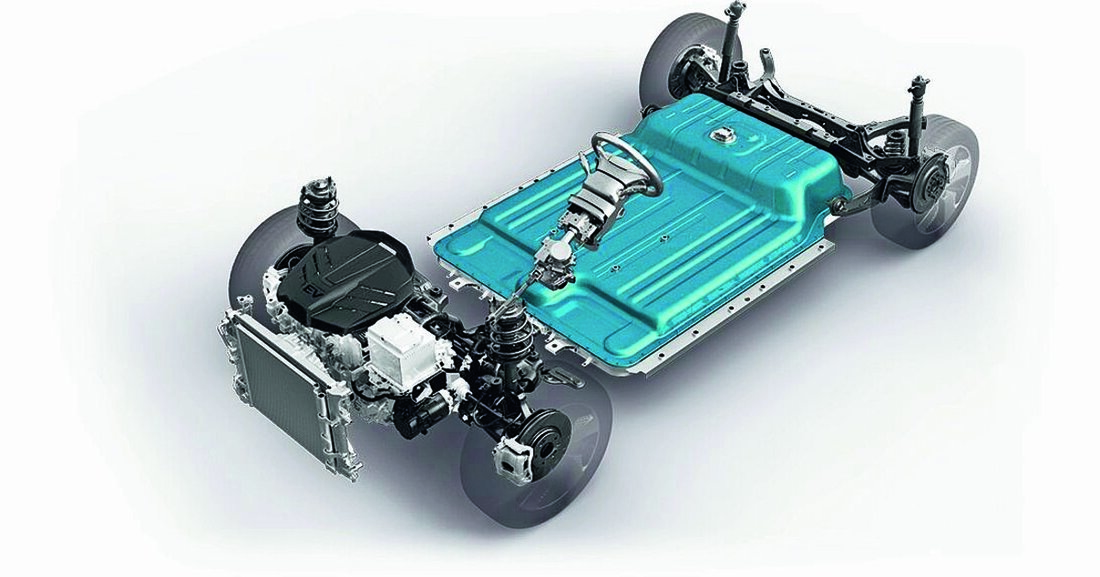

The change in drive technology for cars and commercial vehicles is in full swing. The emissions limits that are constantly being tightened by legislators are making the development of low-emission combustion engines more and more complex, while at the same time the prices for batteries in electric cars are falling. The buzzword “decarbonization” is causing headaches, especially for oil manufacturers, because the age of black gold, in which a car had to be filled with fresh engine oil at regular intervals, is coming to an end. However, engine oil is not the only liquid operating fluid that a vehicle needs for smooth operation, regardless of its drive train. Basically, all moving mechanical parts must be lubricated in order to delay wear and tear for as long as possible.

In addition, battery-electric vehicles usually have a complex cooling system installed for the electricity storage system, the chemistry of which reaches hot temperatures, especially during fast charging and high power consumption. We asked two well-known e-car manufacturers which operating materials their vehicles specifically require and in what quantities. This information is intended to provide independent workshops with guidance on what they will have to prepare for in the medium term when servicing and repairing electric cars.

Cooling and comfort

For the workshop, the loss of engine oil means a severe loss of sales, but this can at least partially be offset by higher maintenance costs for the complex cooling systems of the electric cars. The VW ID.3 with heat pump uses the new environmentally friendly refrigerant R 744, better known as carbon dioxide. The gas, which is liquefied under high pressure, requires a particularly well-sealed cooling circuit and can only be checked and refilled using special air conditioning service devices. The properties of the brake fluid and transmission oil in the electric ID.3 do not differ from the operating fluids in the VW combustion engine models, and the battery cooling is also carried out using the same coolant concentrate as the engine cooling. Hyundai also uses the same GL-4 oil and brake fluid in the reduction gearbox of the Kona Electric as in the manual transmissions of its vehicles with combustion engines. However, there is a significant difference in the coolant, which has a particularly low electrical conductivity in the Kona Elektro and Ioniq Elektro models from model year 2020. In order to keep this low in the long term, a shorter change interval is provided than with conventional coolant. Hyundai also uses a non-conductive special oil for the high-voltage compressor in the air conditioning system.

Oils with new properties

When operating electric cars, lubricants are also used for servomotors such as central locking, for rolling bearings in electric motors, for wheel bearings and as hydraulic oil in ABS and ESP systems.

As a rule, the special oils do not need to be supplemented or replaced, but they do need to be replaced during a repair. In particular, those lubricants that are in direct contact with electrical components must meet certain conditions to prevent sparking and short circuits. They must be compatible with copper wires just as well as with plastic cable sheathing. They should also ensure good heat dissipation of electrical energy and offer protection against wear, oxidation and corrosion. The major oil companies are currently working on the optimal lubricants for electric cars in their laboratories. The objectives are: to optimize power transmission, improve mileage, cool the high-voltage components and thus increase the performance and durability of the vehicle batteries.

Suche

Suche

Mein Konto

Mein Konto