Second life for electric motors

The Fraunhofer Institute is now developing a modern circular economy for electric motors.

Second life for electric motors

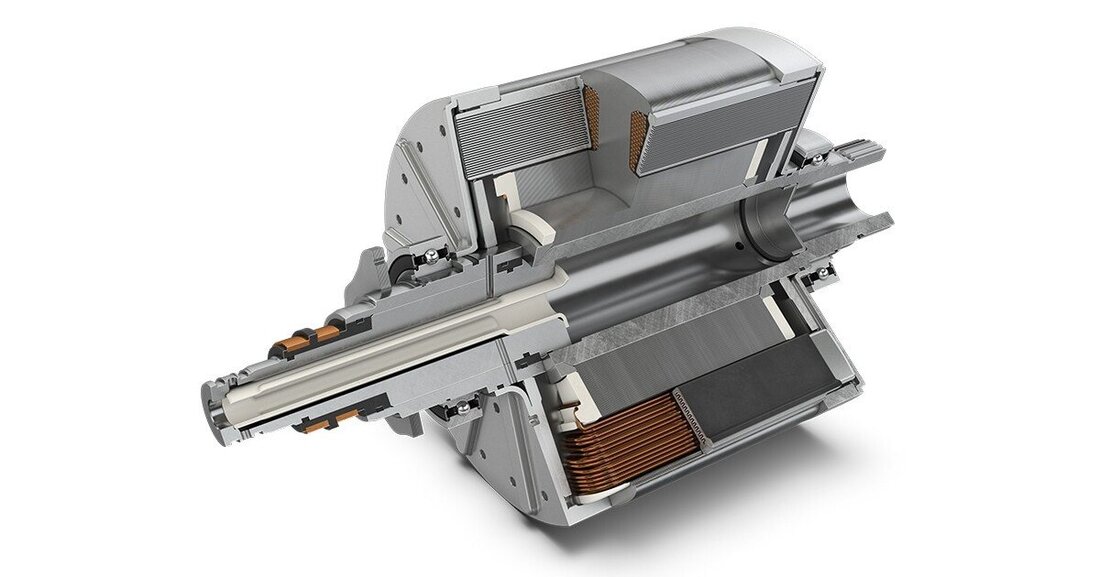

To date, there are no sustainable value preservation strategies for processing and recycling electric motors in the spirit of a modern circular economy. In the “Reassert” project, the Fraunhofer Institute for Production Engineering and Automation IPA, together with industrial partners, wants to enable the repair, refurbishment and reuse of electric motors. These contain valuable raw materials such as copper, but also rare earth metals such as neodymium, on which China has a virtual monopoly and which cannot be recovered using current recycling methods. In addition, the raw materials used have a poor CO2 balance compared to combustion engines. This makes extending the useful life of the engines all the more important. “Innovative value retention strategies offer great potential for reducing emissions in terms of sustainability,” says Julian Große Erdmann, scientist at the Fraunhofer Institute for Production Engineering and Automation IPA in Bayreuth. In the Reassert project, the researchers, together with Schaeffler (consortium leader), the Karlsruhe Institute of Technology KIT, BRIGHT Testing GmbH, iFAKT GmbH and Riebesam GmbH & Co. KG, are developing innovative methods to refurbish electric motors and reuse them in vehicles.

Currently, copper and aluminum components in particular are recovered through recycling. To do this, the electric traction motors are removed, shredded, sorted into individual material fractions and melted down. However, the material that is recycled and contaminated can no longer be used in engines, and individual components and assemblies are destroyed. Therefore, raw material recycling should only be chosen as a last resort and replaced by the high-quality value preservation strategies of reuse, repair, remanufacturing and material recycling. “We want to design a closed-loop system in which valuable resources are reused in order to become less dependent on raw material imports and minimize raw material extraction,” explains Große Erdmann. The project partners understand reuse as the reuse of the entire engine for secondary use, and repair as the replacement of defective components and assemblies. During remanufacturing, all components are removed, cleaned, refurbished and reused. With material recycling, the project partners plan to dismantle the engine according to type before shredding. The project partners analyze which value preservation strategies should be used using reference engines for the passenger car sector. The knowledge collected in the project will be used to design new electric motors. The aim is to develop a prototype of an engine for the circular economy that can be easily dismantled and to which the four value retention strategies mentioned can be easily applied.

Suche

Suche

Mein Konto

Mein Konto