Innovative testing technology for hydrogen tanks

A company from Upper Austria is becoming a pioneer in hydrogen-powered mobility with its patented testing process for hydrogen tanks.

Innovative testing technology for hydrogen tanks

Dorninger Hytronics GmbH from Unterweitersdorf in Upper Austria has developed a patented testing process for hydrogen tanks that saves up to 80 percent of energy, thousands of tons of CO2, raw materials and thus costs. Due to the innovative approach and thanks to the professional advice from Business Upper Austria, the company received a six-figure funding sum for the complex and expensive development. Hydrogen is considered an alternative fuel for future mobility. In order to be able to use hydrogen for mobility, it must be stored in its gaseous state in special high-pressure tanks. The high-pressure tanks are made of carbon fiber and are subject to strict testing criteria. The EU regulation UN R134 stipulates that every 200th tank produced must be tested with 22,000 refueling cycles. The energy required for this is enormous, as the tank has to be put under high pressure and then relieved again - 22,000 times.

Huge energy savings

"If hydrogen becomes established as an additional alternative fuel in mobility, the need for hydrogen tanks will also increase. You can easily imagine how electricity consumption and energy costs for testing the tanks will then explode," says Karl Fischereder, Managing Director of Dorninger Hytronics GmbH. In collaboration with the Linz Center of Mechatronics (LCM), he has developed a patented process that saves around 80 percent of energy and thus thousands of tons of CO2, as well as drastically reducing the material and raw material requirements. This also reduces the costs of the testing process enormously. And this is how it works: Normally, the high-pressure tanks are tested using the constant pressure method. For a typical tank with a capacity of 350 liters, around 8,900 kWh of electricity is required for 22,000 cycles. More than four tons of CO2 are emitted, which costs 1,780 euros at an electricity price of 20 cents per kWh. Dorninger Hytronics has developed a process with regenerative servo pumps in which the tanks are filled 100 percent with water. “This method alone requires 50 percent less energy,” explains Fischereder. "In addition, with the new patented process, we replace some of the water with solid-state spheres. The filling material now only consists of 37 percent water, which has to be compressed. This reduces the energy requirement by another 63 percent." Overall, the method saves around 80 percent energy compared to test stands previously available on the market. In addition, the filling material can be reused for the next test.

Energy in the circuit

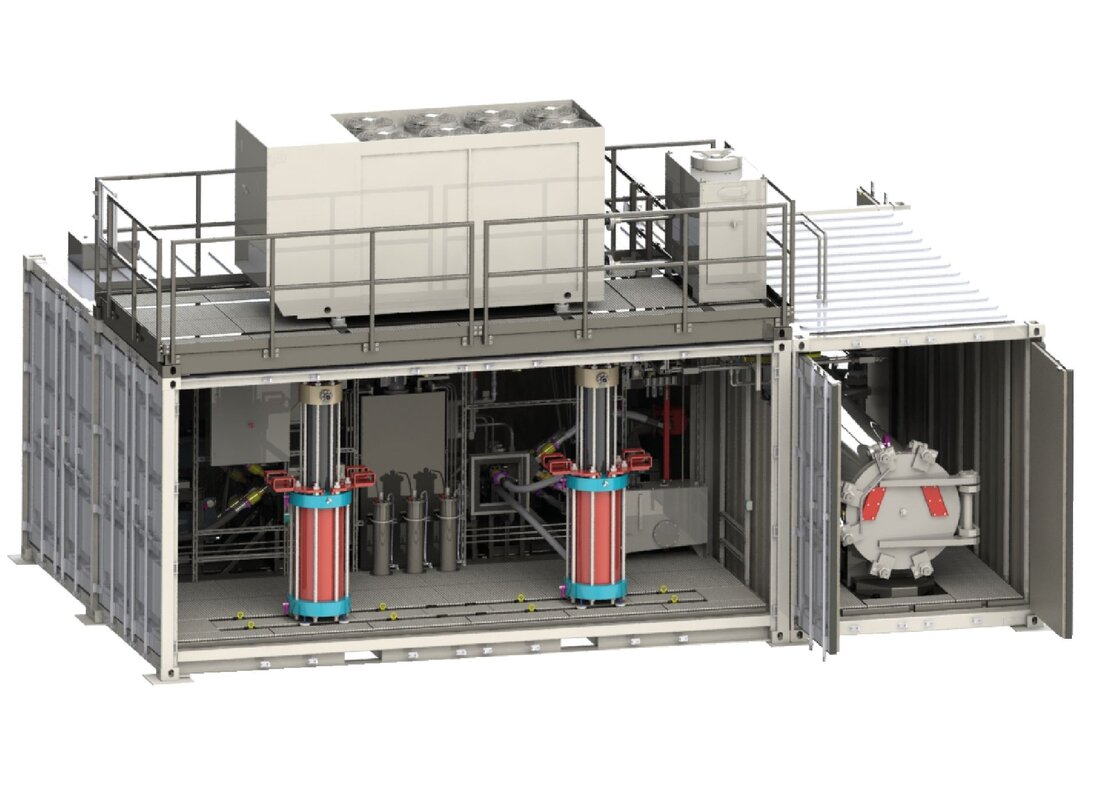

The patented system is even capable of regenerative energy. Hydraulic energy is supplied when loading the tank to be tested. The drive of the servo pump works as a motor and draws electricity from the network. "When the tank is unloaded again, the direction of rotation of the drive is reversed and it becomes a generator. This takes the hydraulic energy, converts it into electrical energy and returns it to the power grid," explains Fischereder. The patented Dorninger Hytronics process only requires 1,780 kWh for 22,000 test cycles. This corresponds to 20 percent of the energy required for testing using the constant pressure process, only emits 0.8 tons of CO2 and costs just 356 euros. The drive requires less power, which also reduces installation and operating costs. The energy required to cool the hydraulic system is also lower and the testing process is safer. Due to the smaller volume of the test medium, the effects on the test bench are less serious if a tank fails during the test. This increases work safety on the test bench, reduces the structural protective devices and enables the construction of a compact test bench suitable for series production.

Suche

Suche

Mein Konto

Mein Konto