Research on electric cars made of wood

The current development of battery housings made of composite materials with wood shows how Austria's supplier industry can benefit from the change towards electromobility.

Research on electric cars made of wood

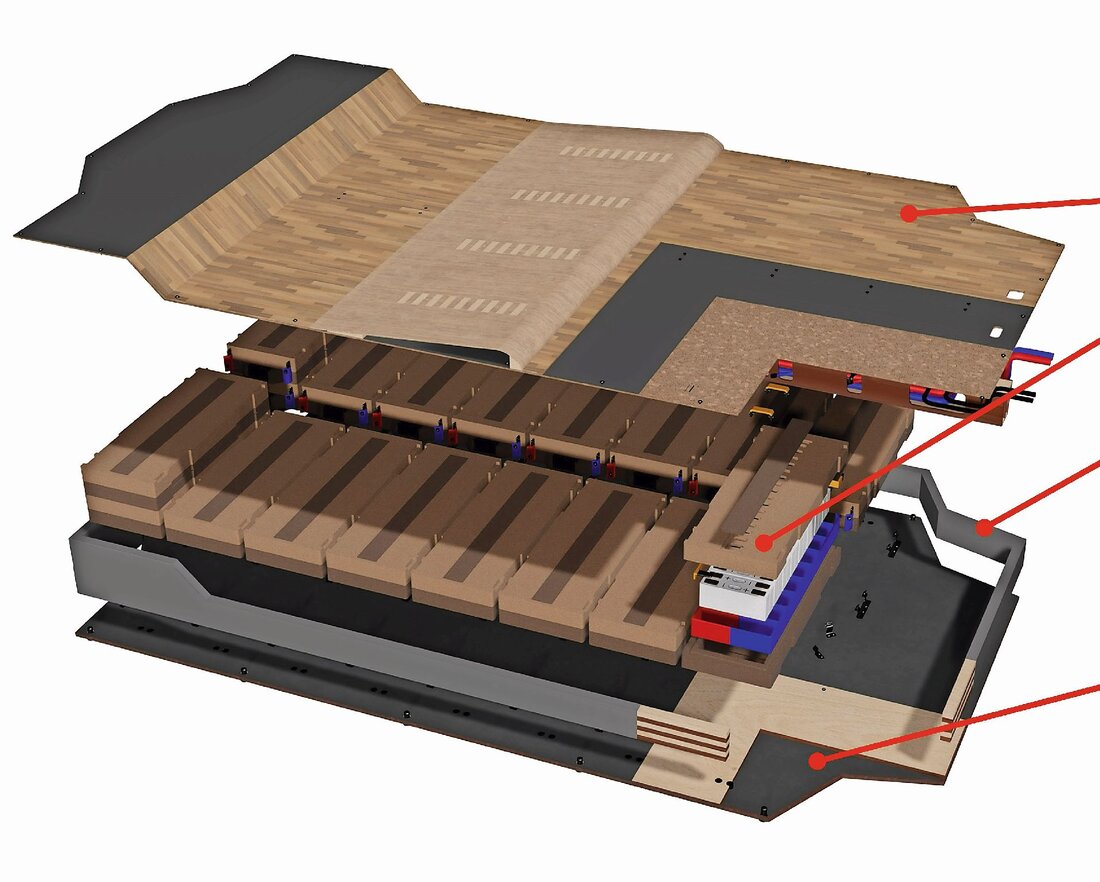

The mobility transition to electromobility offers numerous opportunities for bio-based materials. The research project “Bio!LIB” in the automobile cluster of the Upper Austrian location agency Business Upper Austria is dedicated to battery housings in electric vehicles, which currently consist mainly of steel, aluminum or a combination of both materials. The Austrian approach: “The combination of wood and steel in so-called hybrid structures opens up new possibilities for the construction of battery housings and vehicle structures,” says Gerald Warter, project manager in the automobile cluster. The Graz University of Technology, W.E.I.Z. took part in the research project. Research & Development GmbH, BOKU Vienna and the University of Graz, the automobile cluster of the Upper Austrian location agency Business Upper Austria and the companies Weitzer Woodsolutions, FILL and BUFO technology.

Impressive test results

The wood-steel hybrid beams developed in the “Bio!LIB” project consist of thin steel sheets and cores made of local woods such as birch, poplar or paulownia. In bending load tests that simulated a side pile impact, for example, the hybrid structures demonstrated up to 2.5 times higher energy absorption than conventional multi-chamber aluminum profiles for the same mass and dimensions. “These results underline the enormous potential of wood-steel hybrids in the automotive industry,” explains project manager Florian Feist from Graz University of Technology. “Not only do they offer a sustainable alternative to conventional materials, they even outperform them in critical safety aspects.” The project team developed a prototype in which cork was used as a natural fiber-reinforced composite material. The material, dubbed “hardcork,” consists of 80 percent renewable raw materials and offers the greatest level of fire protection.

Focus on lightweight construction

The follow-up project “SMADBatt” further expands on the promising results. AVL List GmbH and the wood competence center Wood Kplus have now joined the project team. Project manager Georg Baumann from Graz University of Technology emphasizes: “We focus on sophisticated thermal management, a high proportion of secondary raw materials, dismantling and recyclability as well as the lowest possible CO2 footprint.” The project relies on lightweight construction with wood and cork in order to maximize circularity. Gerald Warter adds: “The ‘SMADBatt’ project could pave the way for more sustainable and efficient electric vehicles and show that innovative material combinations can provide surprising solutions to the challenges of the future.”

Suche

Suche

Mein Konto

Mein Konto