E-mobility: New opportunities for suppliers

tesa, Vulkan Technic and Liebherr have jointly developed an innovative solution for battery pack assembly.

E-mobility: New opportunities for suppliers

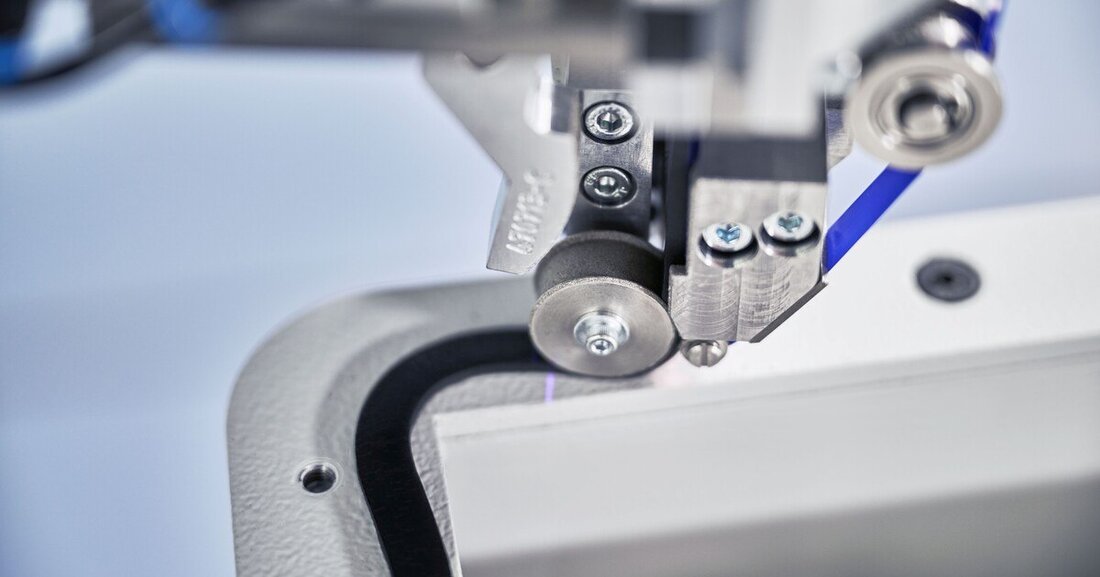

Adhesive specialist tesa contributes the new adhesive seal ACXplus 76730 Box Seal, which, in addition to the clean sealing of battery packs, also makes repairs or later dismantling of the battery pack possible without any problems, Vulkan Technic supplies the appropriate application concept, and Liebherr is responsible for the mechanical implementation as general contractor. Together, the partners are bringing a fully automated assembly line for battery packs onto the market. To date, many individual contacts have been necessary for the bonding and assembly of these battery systems. Now customers can get everything from a single source, with adhesive tape producers, special machine builders and general contractors working closely together. Battery production is thus simplified by implementing an automated and tape-based solution.

Thanks to its suppleness and flexibility, tesa's adhesive tape solution can be applied to battery packs with lids as well as to battery packs that are directly connected to the vehicle underbody. tesa ACXplus 76730 Box Seal does not require any curing time and is easy to apply. “As one of the leading manufacturers of innovative and reliable adhesive solutions for the automotive industry, tesa supports its customers in developing new applications for electrically powered vehicles,” says Boris Kawa, Corporate Marketing Director Automotive at tesa. Sven Neumann, technical sales representative at Vulkan Technic, adds: "The high flexibility of the adhesive tape, which is required to achieve 100% tightness with different gap dimensions, was a particular challenge in the development process. But we found an optimal solution and then implemented it technically." Liebherr was also impressed by the interaction between an innovative adhesive solution and suitable application. "The innovative tesa ACXplus Box Seal promises a secure and automated sealing of the battery pack, but at the same time enables the battery pack cover to be dismantled for rework in the factory. This can streamline the production process because individual intermediate test processes can be replaced by a later end-of-line test by allowing the cover to be opened non-destructively," says Viktor Bayrhof from Liebherr.

Suche

Suche

Mein Konto

Mein Konto