Hydrogen from the tube

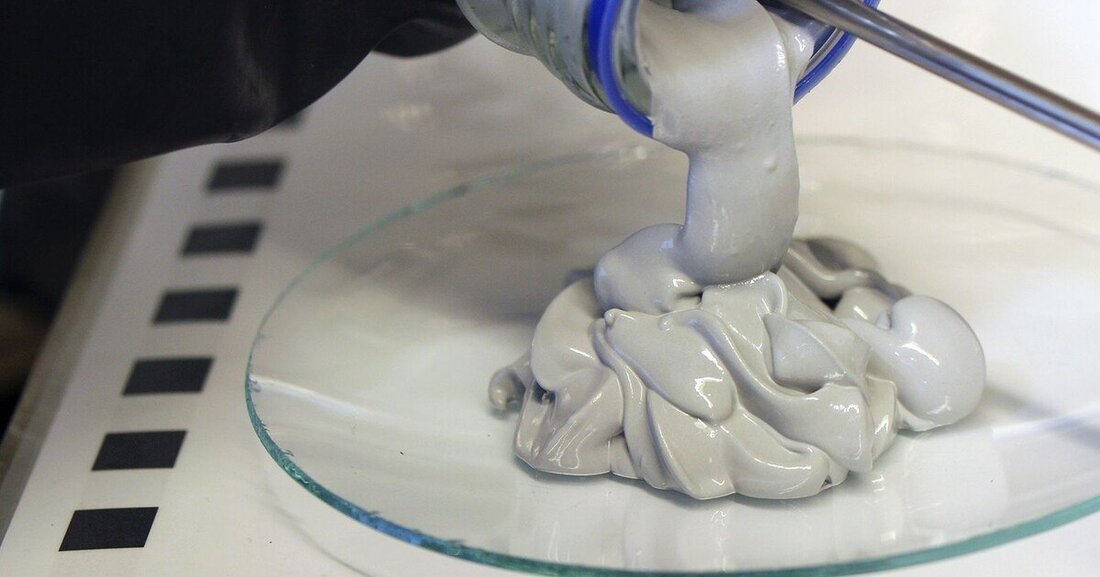

The “power paste” developed at the Fraunhofer Institute in Dresden could give the development of hydrogen vehicles a real turbo boost.

Hydrogen from the tube

So far, gaseous hydrogen has been pressed into the pressure tanks of fuel cell vehicles at 700 times atmospheric pressure. The power paste, on the other hand, consists primarily of powdered magnesium, which is one of the most common elements and is an easily available raw material. To power the vehicle, a stamp transports the power paste from a cartridge into a container into which water is simultaneously fed from a water tank.

High energy storage density

Result of the reaction: gaseous hydrogen. The highlight: Only half of it comes from the power paste, the other half provides the water. “The energy storage density of the power paste is significantly higher than that of a 700 bar pressure tank and is even ten times greater than that of batteries,” says Marcus Vogt, scientist at Fraunhofer IFAM.

A vehicle therefore achieves a similar range with Powerpaste as with the same amount of petrol. A production facility is now being built at the Fraunhofer Project Center for Energy Storage and Systems ZESS. This is scheduled to go into operation at the end of 2021 and will then produce up to four tons of hydrogen paste per year.

Suche

Suche

Mein Konto

Mein Konto