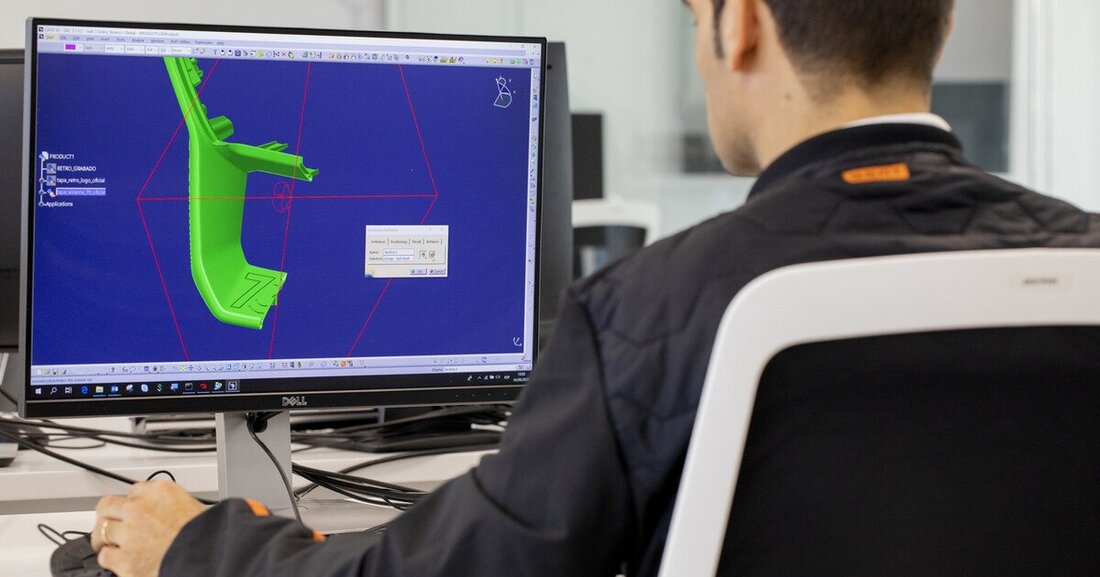

Prototype parts from the 3D printer

Seat provides insights into the advantages of prototyping when 3D printers are used.

Prototype parts from the 3D printer

Manufactured without molds, without design restrictions and ten times faster: 3D printing offers almost countless possible uses. The automotive industry was among the first to take advantage of this technology to save time and be more flexible in all phases of a vehicle's development and production. In the case of Seat, the in-house 3D printing laboratory is located in the Seat prototype center.

"One of the advantages is that we have virtually no restrictions on the possible shapes and can produce high-precision designs for all areas of the factory - no matter how complicated they appear. And all of this in a time that is unachievable with normal manufacturing processes."says Norbert Martín, head of Seat's 3D printing laboratory.

In addition to the diverse design possibilities, the most important advantage of 3D technology is the speed at which the parts are manufactured. In the traditional process, for example, to make a mirror, a mold must first be made. That alone can take weeks. Furthermore, it would be a unique model and a new mold would have to be made for even the slightest change. With 3D printing, this complex step is no longer necessary. The technicians receive a file with the design and send it to the printer just like a document. After about 15 hours the part is finished.

"Using traditional technologies, this would take weeks. Thanks to 3D printing, we are able to produce multiple versions in the same week, which can be tested and further improved through further modification.", explains Martin. Re-producing a mold when making changes to the design not only costs time, but of course also money and resources. For 3D printing it is enough to change the design file.

Suche

Suche

Mein Konto

Mein Konto