#PimpMyDuke: Part 4 - Suspension Upgrade

The APEX Duke gets a proper chassis service and upgrade. The fork and shock absorber are completely overhauled and retuned. Not without reason, as a chassis test run reveals after a few minutes.

#PimpMyDuke: Part 4 - Suspension Upgrade

When I had the idea to build an old KTM 990 Super Duke, many people asked me why: “What do you want with the old planer?” or “The box has neither power nor does it drive well, why bother?” I think the old Super Duke is an extremely underrated motorcycle. Firstly, it has just enough power that you can get it onto the asphalt without any electronic help. And their handling has enormous potential. Because the mix of naked bike and supermoto is great, especially on country roads. Very agile at corner entry but significantly more stable than most supermotos. Crucial point: The feeling for the front wheel is a bit difficult. This makes it clear: the chassis professional has to fix it. For me personally the best address at the moment: WiRo motorcycle technology in Klagenfurt. The owner and head screwdriver is Robert Wilhelmer. I've known Robert for years, and now no one else attacks my undercarriages. Not because I'm related to Robert or anything, no, but "The Rob" always understood my wishes for a chassis: firm, but please not hard. With feedback, but not bony or bitchy. I've already tried a few suspension specialists. Everyone was able to improve my chassis. But each one was too hard for me personally. Great for flat tracks with non-slip asphalt, but as soon as things got bumpy and the surface was wavy and patchy, the racing chassis was too hard. Instead of sliding over the bumps, I was usually on the verge of jumping. Unfortunately, that only makes one thing: terribly slow. Because the chassis has to work and relieve the pressure on the tires as much as possible. Robert has always been able to do this for me so far, so it was clear that the APEX-Duke would only be set up by him.

High-tech from A to Z

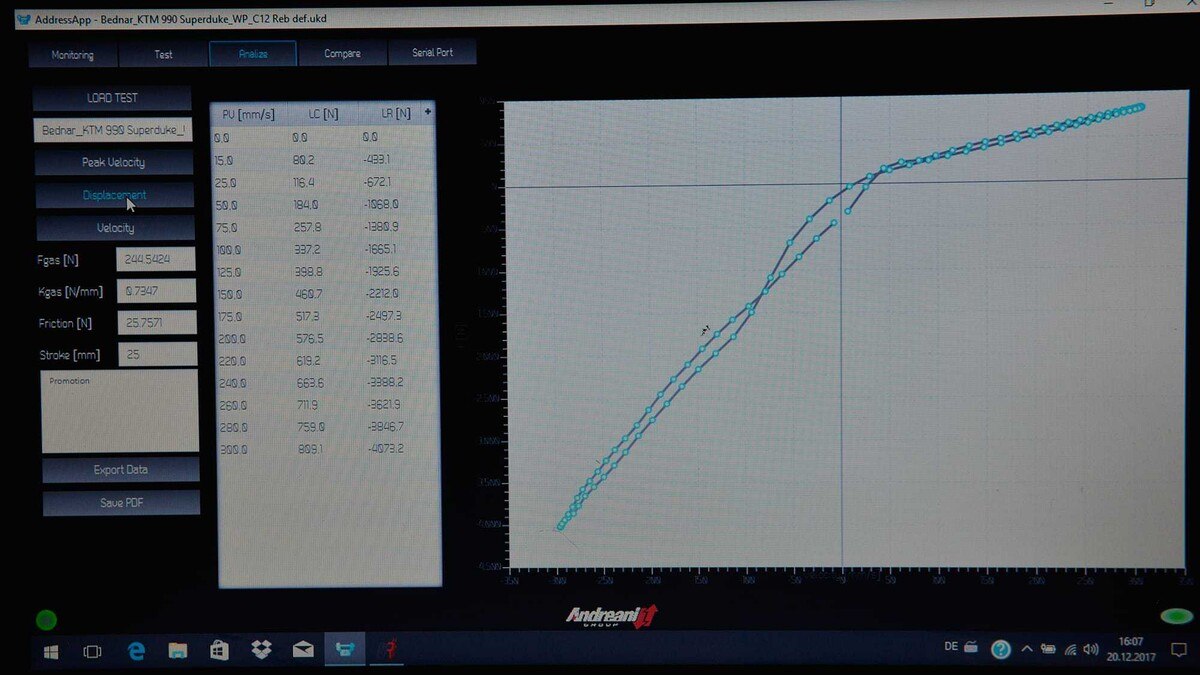

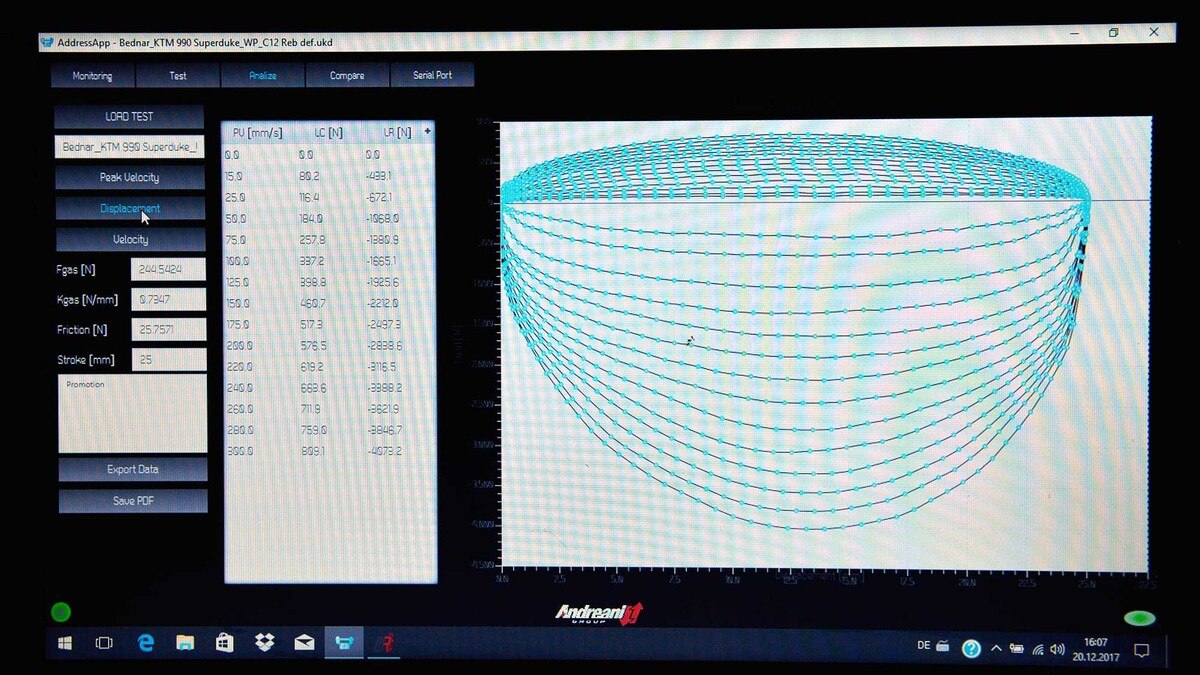

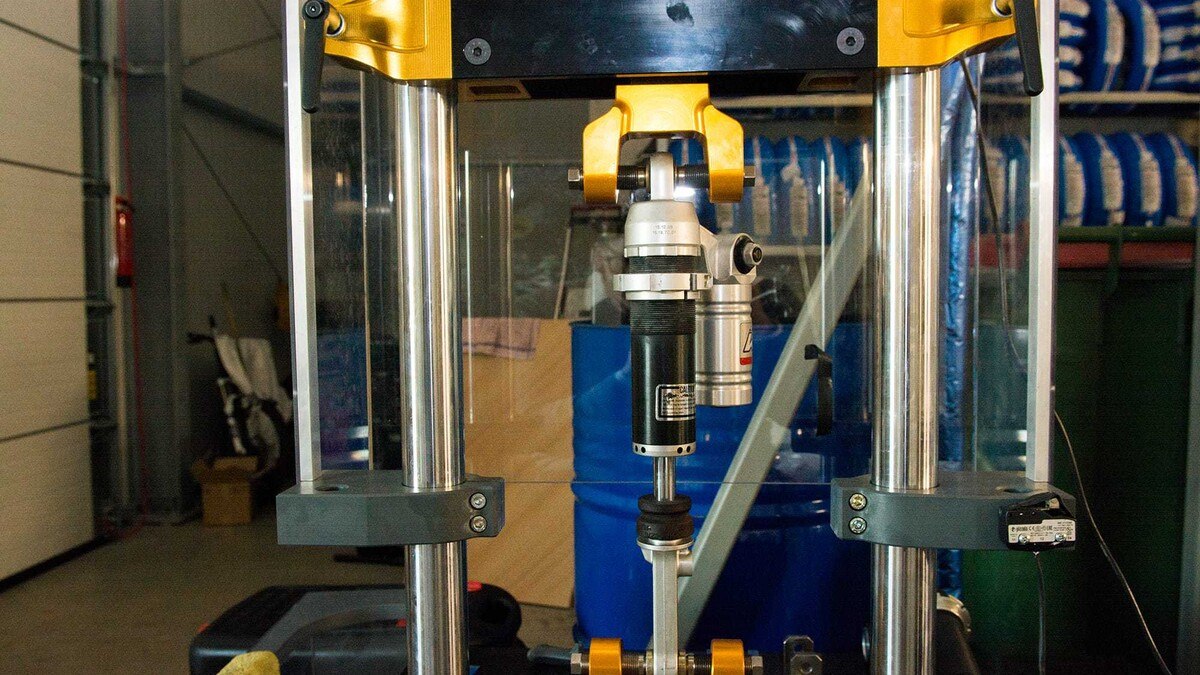

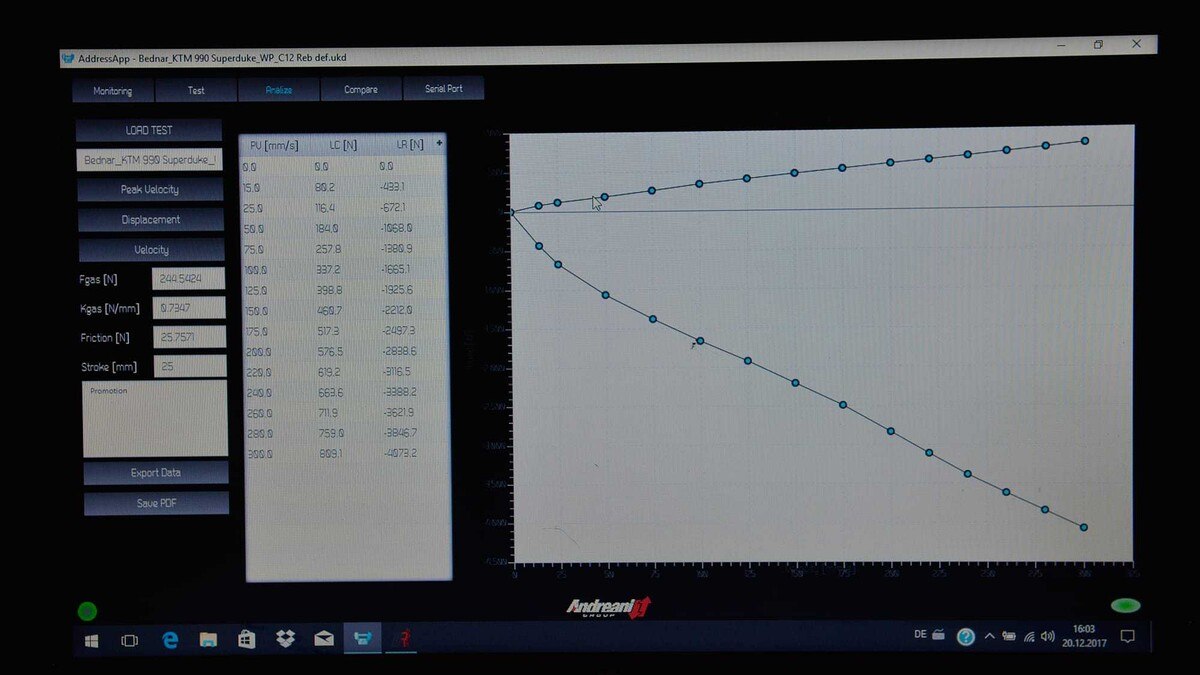

Without wanting to give Robert too many roses, but one advantage of his way of working is right in the middle of the workshop: the chassis test bench. This means that the suspension strut tuning and functionality can be precisely, dynamically determined, evaluated and controlled. The shock absorber or fork leg is clamped and compressed and extended at different speed levels. The connected computer spits out the attenuation curves. The curves mean absolutely nothing to a layman like me, but Robert can see where there are problems with the response and feedback. In with the original WP shock absorber, test bench on, test run. Result: Rebound (controls the rebound speed) way too tight. According to Robert, most street KTMs ride with a tight rebound, but these values are abnormal. However, the error was quickly found: the rebound adjuster got stuck due to the KTM being used in winter. Nothing moved at all there. It needs to be replaced. In addition, the setting of the rebound and compression stage must be adjusted or harmonized. The professional speaks of Hysteresis. Never heard of it before in connection with chassis? Me neither. But that's why we're with Robert, he knows that, he can do it, he's already doing it. By the way, the spring rate of the Super Duke was not changed for my weight (approx. 90kg ready to ride).

Service plus coordination

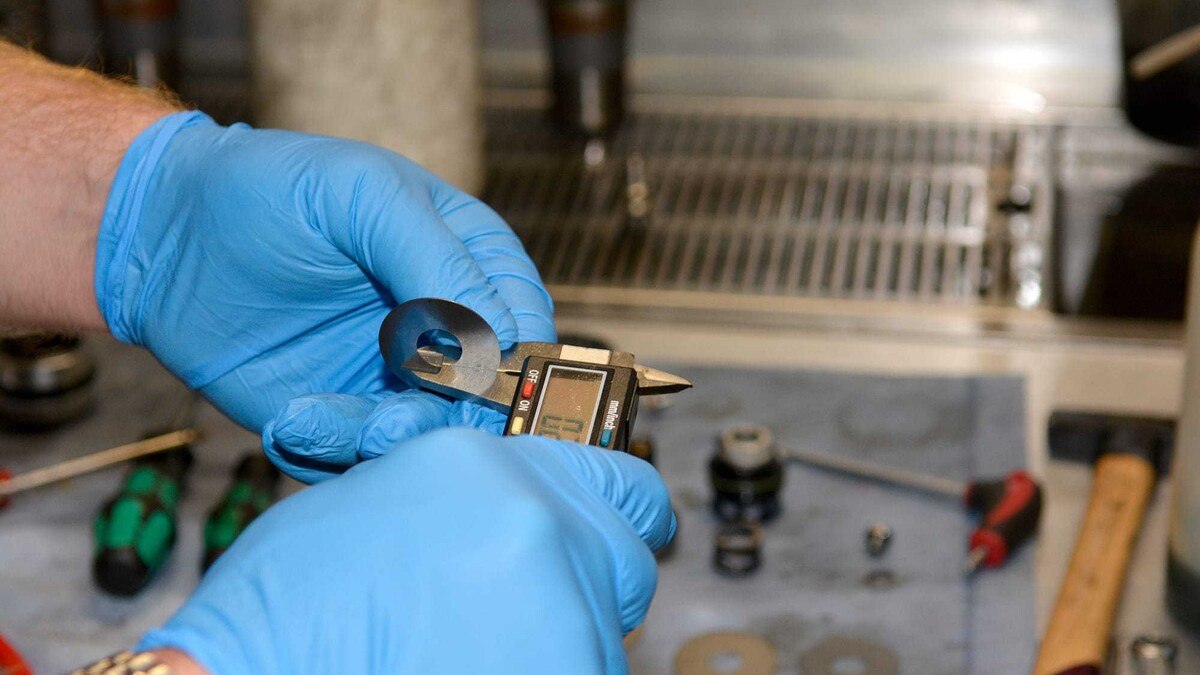

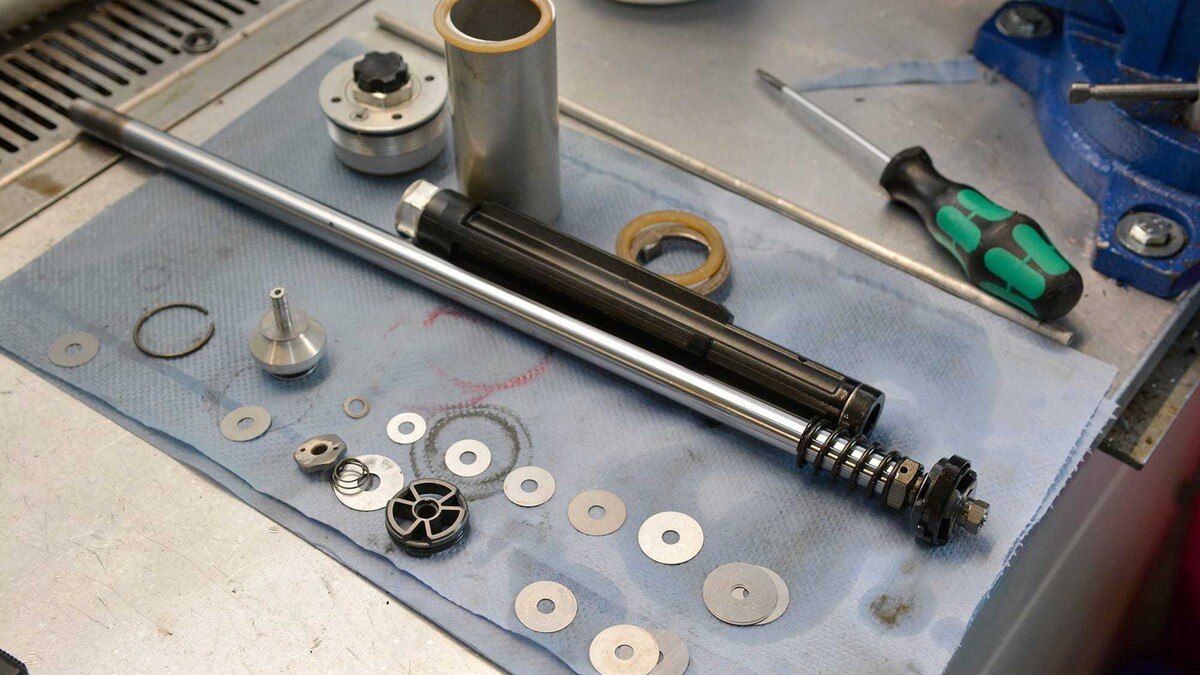

The fork bars are not put to the test, so just pressing Robert while stationary is enough to know in which direction work needs to be done. There are no negative surprises when disassembled, rather the opposite: Although the APEX Duke has already covered almost 28,000 kilometers and has been on local roads since 2007, the sliding bushings of the WP fork are in very good condition - an advantage of the three-part bearing. No exchange necessary. The fork seals are of course replaced, as are the fork oil and fork springs. In addition, the stroke of the fork is increased by 10 millimeters, which should improve steering behavior and braking. This simply gives the fork more travel to work with and can therefore handle larger bumps. For clean response, a Bel-Ray fork oil with viscosity level 7 is filled. Why such a thin fork oil? The thinner the fork oil, the more consistent it is with temperature fluctuations. Just thick oil for more damping is nothing, as Robert knows: "The KTM has a fully adjustable fork with a cartridge system. We don't need thick oil to increase the damping, but we will equip the damper piston with a different shim setting. This will solve the problem and not only alleviate it." The shim plates, with different thicknesses and diameters, are largely responsible for how quickly the damper oil flows through or over the damper piston. The exact composition of the extremely thin metal plates is the big secret. Years of experience is necessary, as well as some basic knowledge and just trying things out every now and then. To find the right fork setting on the APEX-Duke, Robert needed three attempts. This means: completely disassemble the fork three times, clean it, reassemble the shim package, assemble it and press it. Until the fork experiences hydraulic damping on the first millimeter of travel and reveals the responsiveness that allows it to push into the radius both slowly and really quickly.

Service is mandatory

Many motorcyclists change their engine oil and filter every year. Great thing. Fortunately, this is not necessary with the chassis, but regular chassis service should be planned for every motorcycle. The chassis ensures that the tires are always guided safely over the asphalt and thus build up grip. That grip that we all want to have in abundance when braking, accelerating and turning, so that we can drag everything but our butts. From my own experience, I can report that even a five-year-old chassis responds worlds better after a service and noticeably increases driving pleasure. It works more precisely, has a more constant temperature and - if you can adapt it to your own needs - exactly the way you always wanted it. Savings tip: Have your suspension tuned right away during your first suspension service. The additional cost is quite small compared to the service costs and the result is clearly noticeable.

Suche

Suche

Mein Konto

Mein Konto