Electric axle: The new drive train

Car manufacturers' suppliers are introducing new compact drive units for electric vehicles. Bosch, Continental, ZF and Schaeffler are fighting for pole position in the exploding future market of electromobility with their ELECTRIC AXLES.

Electric axle: The new drive train

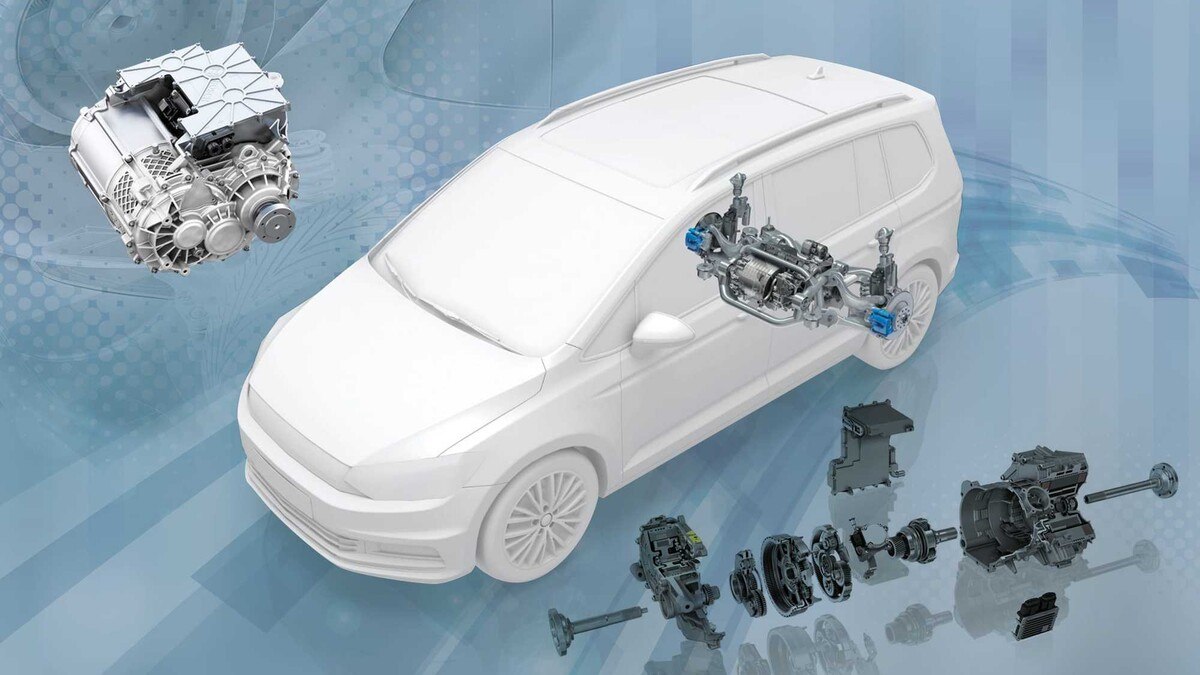

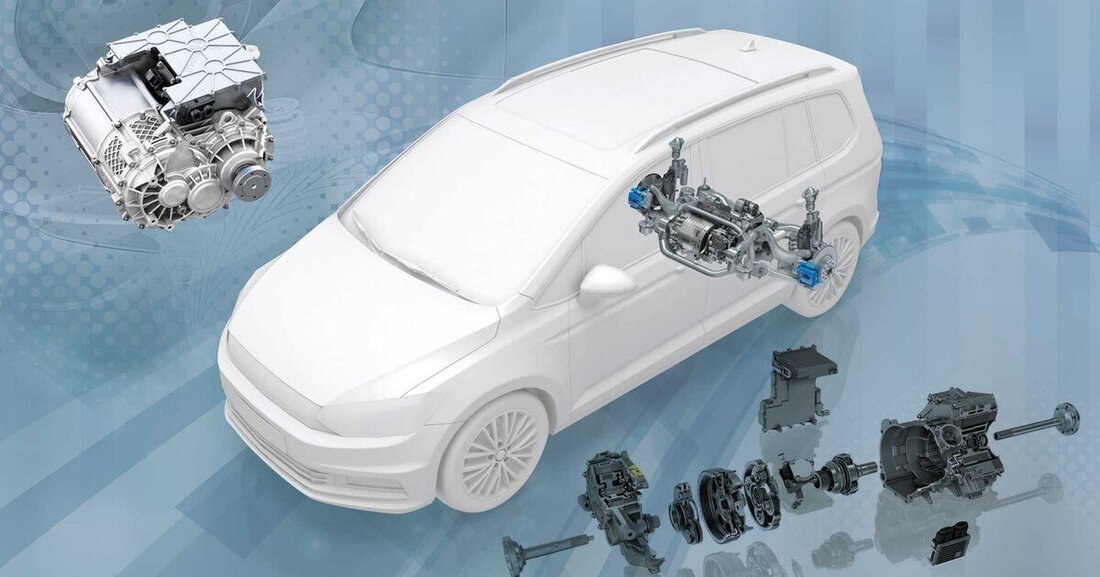

The principle is as simple as it is ingenious: electric motor, transmission, power electronics and differential are put together into one package and can be installed in any vehicle, from small cars to large SUVs, instead of the front or rear axle. All-wheel drive vehicles are simply equipped with two electric axles, and the new drive concept is also an impressively simple solution for hybrid and fuel cell vehicles. It's no wonder that all the major automotive suppliers, whose core competence has previously been the development of components for the combustion engine, are working hard on the development of electric axles. The race is expected to go to ZF Friedrichshafen AG, which has announced that it will mass-produce its compact electric drive module at a European automobile manufacturer as early as 2018. A year later, Bosch and Continental brought their series-ready electric axles onto the market, and Schaeffl also reported that an electric axle was about to be introduced into series production.

“The e-axle is the start-up drive for electric cars.”ROLF BULANDER, BOSCH MANAGING DIRECTOR

HOPE FOR BILLION SALES

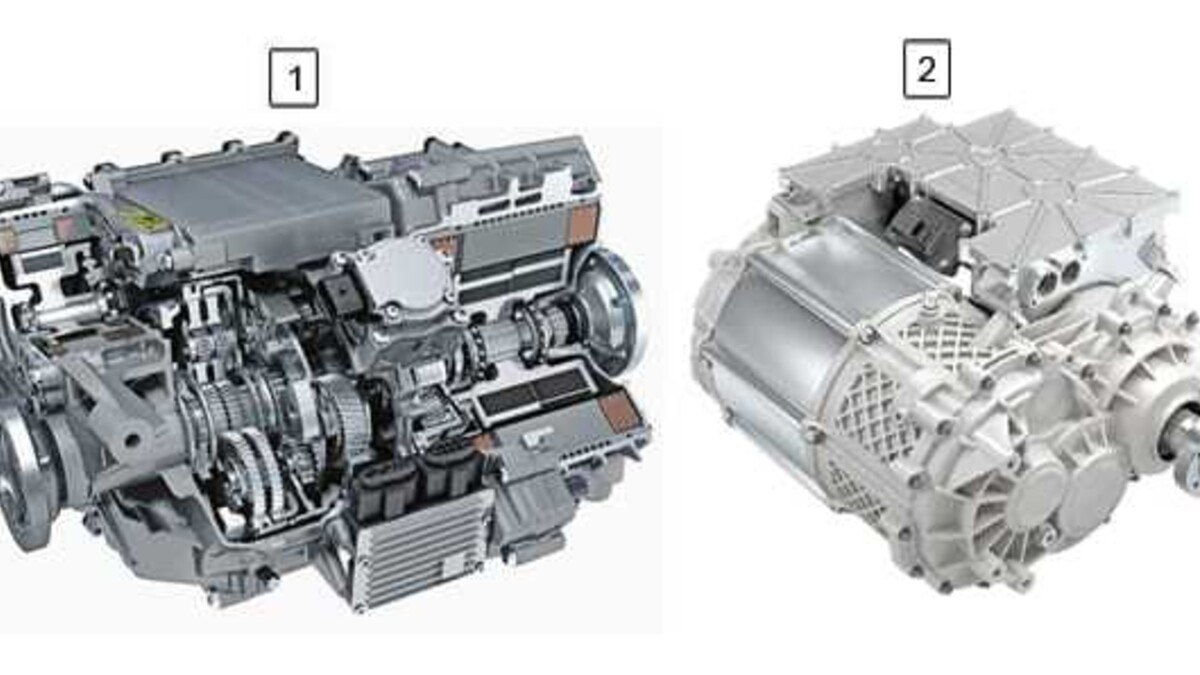

“Economically, the e-axle can be a big success for Bosch, because Bosch is bringing the all-in-one principle into the drive,” says Rolf Bulander, Managing Director of Robert Bosch GmbH and Chairman of the Mobility Solutions division. Bosch hopes to generate billions in sales from this component alone. "The e-axle is the startup drive for electric cars - even for established car manufacturers. This saves them expensive development time and can bring electric vehicles to market much faster," says Bulander. The power of the drive can be scaled between 50 and 300 kilowatts, the torque between 1,000 and 6,000 Newton meters. An electric axle with an output of 150 kilowatts only weighs around 90 kilograms, which is significantly less than the components of a conventional electric drive. Supplier Continental is building its new, highly integrated electric drive module to be even more weight-saving. With an output of 150 kilowatts, it weighs only 75 kilograms - also including the electric motor, power electronics and transmission. Continental offers car manufacturers its completely electric axle drive in power classes of up to 320 kilowatts and, depending on the gear ratio, with an output torque of up to 6,400 Nm. The market launch is scheduled for 2019 in China.

“The automotive industry is on the path to zero-emission mobility.”PETER GUTZMER, BOARD OF SCHAEFFLER TECHNOLOGY

MODULAR PRINCIPLE

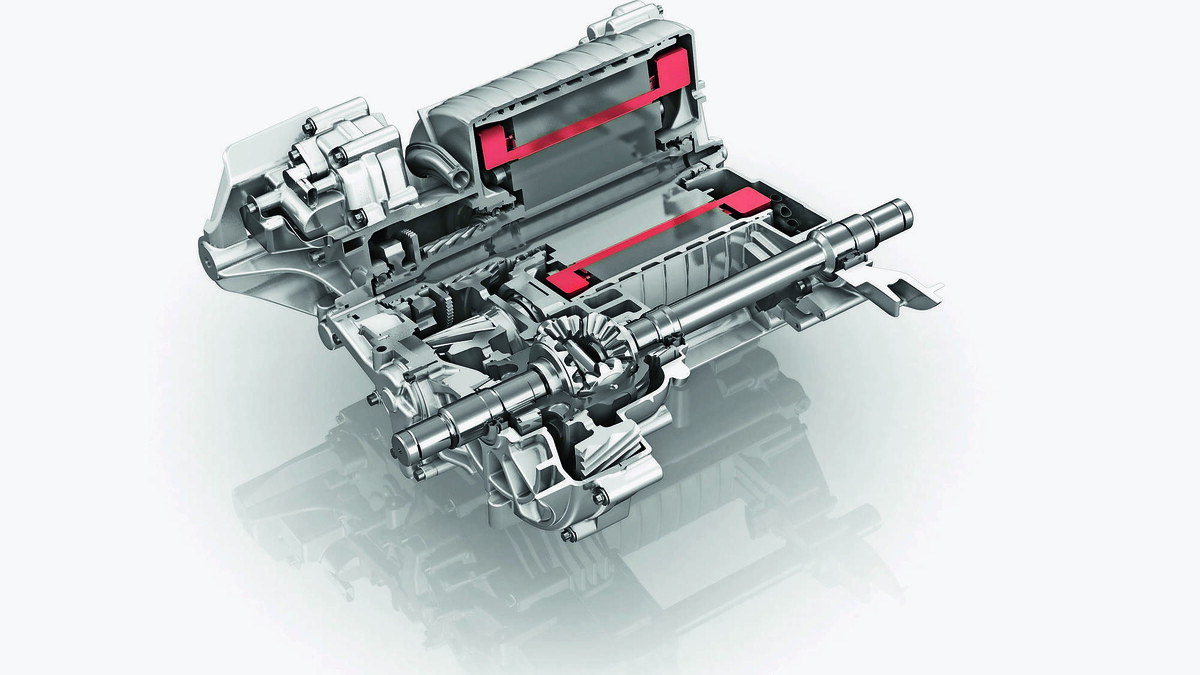

Supplier Schaeffl presented its latest generation of e-axles at the IAA. In its simplest form, the modular solution for hybrid vehicles and pure electric cars offers a single-speed translation in a coaxial or axially parallel design. Due to the planetary design of the differential, the transmission is extremely compact and offers a lot of space for the electrical machine, which can be designed as a PSM (permanently excited synchronous machine) or ASM (asynchronous machine) with or without power electronics. The basic configuration can be expanded with additional functional elements such as a parking lock. A second gear is particularly necessary in plug-in hybrid vehicles, where dynamic, purely electric operation up to 120 km/h and at the same time a high top speed are required. In the two-speed axle developed by Schaeffl, the lateral dynamics are controlled by a small electric motor including a gearbox. “No one can currently say how quickly purely electric vehicles will establish themselves on the market,” said Schaeffl Technology Director Peter Gutzmer at the IAA. Nevertheless, he is convinced: “The entire automotive industry is on the way to zero-emission mobility, and we want to support this trend with technologies that are ready for series production.”

INTEGRATED SYSTEMS

Supplier ZF has been producing large-scale electric motors, axle drives and electronic controls for automobile manufacturers for a long time. In 2018, the company started series production of its first e-axle for a European manufacturer. “The efficient and compact drive system from ZF shows that the system integration of transmission, electric motor and power electronics is a key competence that we can offer our customers from a single source,” says Jörg Grotendorst, head of the new E-Mobility division at ZF. The modular approach to electric axle drives covers the requirements of different customers and models with different performance classes and lengths - from compact cars to light commercial vehicles. An electric asynchronous machine (ASM), a two-stage single-speed transmission, differential, housing and cooler as well as the power electronics and software are integrated into the ZF-E axle. The motor and gearbox share a housing, which simplifies production and final assembly. The system delivers up to 150 kW and a maximum axle torque of 3,500 Nm. The compact drive system measures 45 × 38 × 51 cm and weighs 113 kilograms. An integrated cooling system regulates the optimal operating temperature of the electric motor and electronics.

“We offer our customers a compact drive solution.”JÖRG GRODENDORST HEAD OF DIVISION E-MOBILITY ZF

Suche

Suche

Mein Konto

Mein Konto