Battery research: slow progress

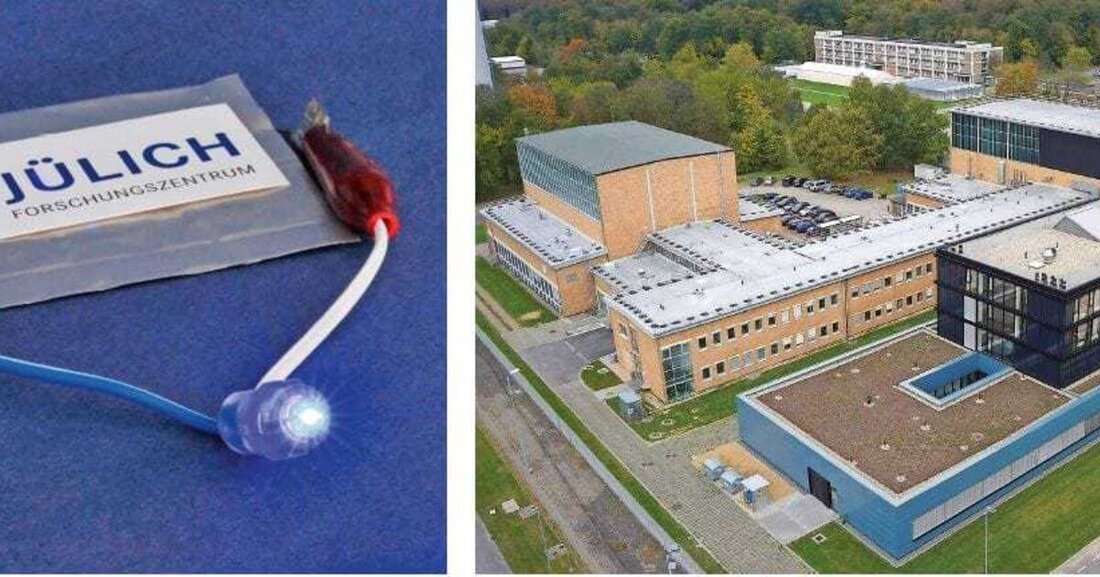

MARTIN FINSTERBUSCH leads the development team for solid-state batteries at the German research center Jülich. In an interview with KFZ Wirtschaft, he reveals why we will probably have to wait over a decade for a significantly more powerful battery generation.

Battery research: slow progress

“Solid-state batteries are among the hot candidates for the next generation of batteries.”MARTIN FINSTERBUSCH

Automotive economy: The next generation of solid-state batteries should be twice as powerful and safe as today's lithium-ion batteries. What's true about the car manufacturers' promises?

Martin Finsterbusch: In fact, solid-state batteries are among the hot candidates for the next generation of electric mobility batteries. Since they no longer contain liquid electrolytes, they are leak-proof and temperature-stable, unlike today's generation of lithium-ion batteries. At our research institute we are also working on doubling the energy density and improving long-term stability.

How far along are you with your research and when can we expect the new generation of batteries to be ready for the market?

If tomorrow one of my employees solved all the remaining physical and chemical problems in one fell swoop, it would only take two years. In fact, we still have a few hurdles to overcome, as our cells only function on a laboratory scale for the time being. The big challenge now lies in scaling the function of the individual small cell to the battery pack of several hundred large cells in a vehicle. In the next step, the materials and manufacturing processes must be optimized in terms of cost efficiency, as every cent counts in automobile manufacturing. I therefore do not expect functional prototypes before 2025 and possible large-scale production before 2030.

Car manufacturers such as Toyota and Fisker, as well as vacuum cleaner manufacturer Dyson, want to bring solid-state batteries onto the market in the early 2020s. Is there any truth to this, or are they just rumors?

If I knew that, I wouldn't be a physicist, but a clairvoyant(laughs). Many research laboratories around the world are currently working on new disruptive battery technologies in the strictest secrecy. Nobody can say today who will ultimately win the race.

You hear about different concepts such as lithium-sulfur, lithium-air or even lithium-glass batteries. Which do you think is most promising?

At the Jülich Research Center we are primarily working on the development of oxide-based ceramic solid-state batteries. Although these have greater manufacturing challenges compared to sulfur or phosphate-based solid-state batteries, they are also the most stable. We develop the starting powders, semi-finished products and functional layers and use them to build complete cells. We have many years of know-how and a large portfolio of ceramic manufacturing and processing processes at our disposal, with which we can combine a wide variety of materials and produce different cell types. The focus is always on developing materials and processes that are as cost-effective and scalable as possible.

Would you personally buy an electric car today or would you rather wait for the next technological leap in battery development?

There will probably not be a major technological leap in the next few years, but rather a gradual evolution of battery technology. After all, the lithium-ion battery with liquid electrolyte has been around for 25 years and is constantly being further developed. That's why I'm already interested in buying an electric car, but I've noticed that I often don't get competent answers from dealers to my questions about the vehicle batteries currently installed. In addition, the charging infrastructure is not yet sufficiently available for my mobility needs, so I would rather wait a little longer.

TO PERSON

Martin Finsterbuschstudied technical physics at the TU Ilmenau. After research stays in the USA, he received his doctorate in 2011 on degradation mechanisms of cathodes in oxide ceramic fuel cells (SOFC). In the same year he moved to the Jülich Research Center in the solid-state battery area, and in 2016 he took over management of the development team.

DATA & FACTS ABOUT FUNDING

New registrations:According to Statistics Austria, 401 purely electric cars were newly registered for use in January 2018, which is 18.3 percent more than in the same period in 2017. In the previous year there were a total of 5,433, in 2016 there were 3,826, and in 2015 there were 1,677. As of January 2018, a total of 14,994 electric cars are on Austria's roads.

Infrastructure:There are currently 1,900 public charging points between Vienna and Bregenz, all of which are equipped with the current Type 2 charging plugs. Almost 90 percent of all electric vehicles are charged at home, less than ten percent charge electricity on the go, and almost 5 percent use fast charging stations.

Funding:Since March 1, 2017, the purchase of electric cars has been subsidized throughout Austria with 4,000 euros, plug-in hybrids with 1,500 euros. In addition, the purchase of a wallbox for charging or the purchase of a charging cable is supported with 200 euros. There are also state grants in Lower Austria, Salzburg and Upper Austria.

Suche

Suche

Mein Konto

Mein Konto