BASF is building a battery recycling plant

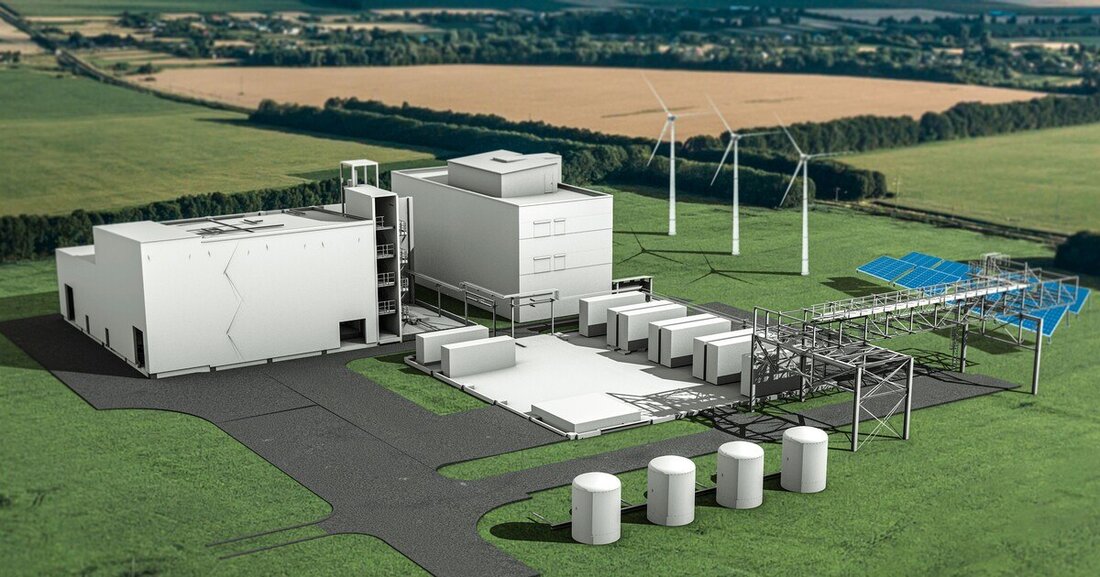

BASF will build a prototype battery recycling plant in Schwarzheide, Germany, at the site of its cathode materials plant.

BASF is building a battery recycling plant

The BASF battery recycling prototype plant enables the development of operating procedures and technology optimization to achieve higher recovery of lithium, nickel, cobalt and manganese from end-of-life lithium-ion batteries. At the same time, the facility can also recycle metals from products from cell manufacturers and battery material manufacturers that do not meet product specifications. Given the expected rapid growth of the electric vehicle market, recycling offers competitive and sustainable access to relevant metals for cathode materials. The metals obtained are used to produce new cathode materials and enable a circular economy for the battery value chain.

Raw material cycle

“By investing in battery recycling and our leading process technology for the production of cathode materials, we want to close the loop and at the same time reduce CO2-Reduce the overall footprint of our cathode materials by up to 60 percent compared to the industry standard," says Matthias Dohrn, Senior Vice President Precious and Base Metal Services in BASF's Catalysts division. "In this way, we meet the requirements of our OEM customers in the automotive industry and contribute to a more sustainable future for all of us." The investment will create around 35 new jobs in production, with commissioning scheduled for early 2023.

Suche

Suche

Mein Konto

Mein Konto