AVL optimizes battery testing

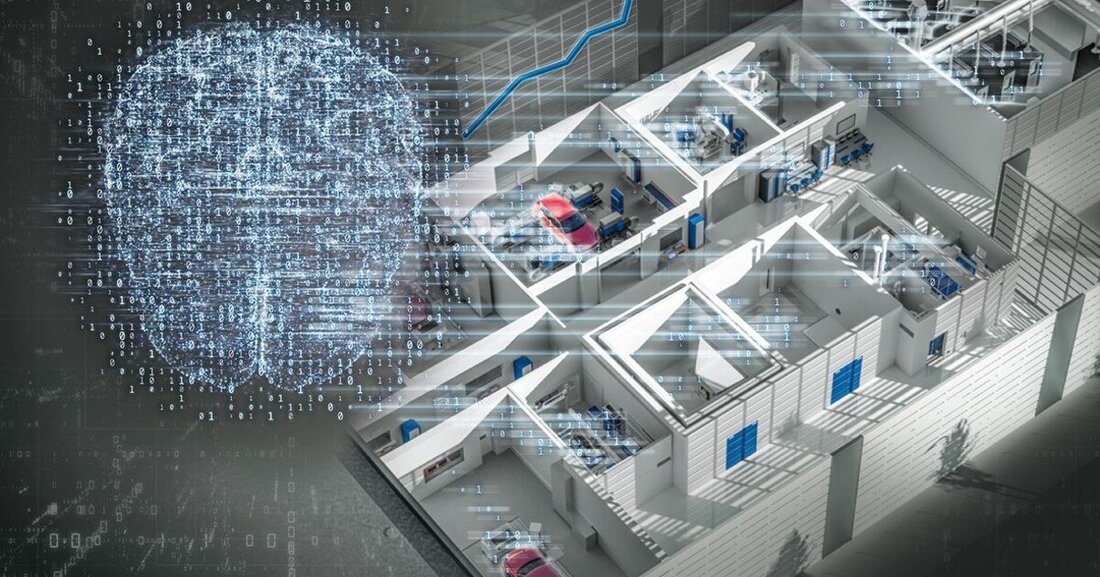

AVL has developed the data and process management software solution AVL Lab Management for Battery to make battery testing more efficient.

AVL optimizes battery testing

Battery cell testing is characterized by a large number of test specimens in a short period of time and therefore requires coordinated planning and implementation of a large number of different tests. The test field team must monitor numerous battery cells, battery modules and battery packs and at the same time carry out activities such as setting up, setting up and dismantling test units. The AVL Lab Management for Battery software solution handles these tasks using intelligent logistics functions and test planning algorithms for large numbers of test specimens. Central data management ensures the best reusability and traceability of all collected data and provides the basis for automated, decision-relevant reports. AVL Lab Management ranges from test bench reservation, order planning, test preparation and test execution to data management and data post-processing. Increasing test field efficiency and reducing test effort are crucial for test field operators to remain competitive in the face of the increasing complexity of electrified powertrain systems and the increasing number of model variants. The openness to other hardware or software manufacturers as well as the high scalability and optimal flexibility of the AVL Lab Management solution allows it to grow with customer requirements. “This means our customers are optimally prepared for the dynamic changes facing the industry,” says Marinette Iwanicki, AVL product manager.

Suche

Suche

Mein Konto

Mein Konto